This "Massive Win for Passive" codifies Passive House for new multi-family construction in the state, which aims to achieve net-zero emissions by 2050 statewide.

Massachusetts has officially raised the bar for building performance—at least in communities that have opted in to the state’s “specialized energy code” tier to meet building code compliance with Passive House certification. Already, 55 of municipalities in the state have opted in to this highest tier, representing at least 18% of the state’s total population, according to the latest available census data.

This is a big deal. It means that in these 55 (and counting) municipalities, any new multi-unit, or multi-family, residential buildings over 12,000 square feet must meet Passive House energy efficiency standards. According to the Massachusetts Clean Energy Center, 224 multi-family buildings in the state with approximately 6,000 units were on track as of March 2025 to meet this standard.

What does it mean for residential building? Residential buildings of varying sizes and fuel types (mixed fuel or all-electric) can choose between a Phius/PHI certification or a specific HERS rating to meet the minimum efficiency requirements. (See page 9.)

How does the state code define a multi-family building? A document from the Massachusetts Department of Energy Resources sheds some light. It says: "Multi-family buildings built to the Commercial Specialized Code must achieve precertification to Passive House standards (either from PHI or Phius). These requirements are phased-in for buildings up to 5 stories required to meet Passive House requirements if applying for permits after January 2023, and taller buildings 6 stories and above required to meet Passive House for permit applications beginning in January 2024."

(Page 9 of the document includes a table of compliance requirements by building type, size, electrification, fuel type, etc.)

The list of municipalities opting into the specialized code requirements continues to grow as the state pursues its goal of net-zero emissions by 2050 statewide. The City of Boston recently became the eighth—and by far the largest—municipality in Massachusetts to opt in, making it the first major U.S. city to mandate Passive House compliance in its building regulations. Boston’s leadership sets a bold precedent for climate action and high-performance building in urban settings.

Passive House is no longer a niche approach—it’s becoming the benchmark for high-performance construction. Its stringent thermal performance and airtightness targets ensure buildings not only exceed today’s codes, but are future-ready for evolving energy standards. With generous state incentives supporting both Passive House design and all-electric systems, municipalities are proving that sustainability, housing affordability, and developer viability can go hand-in-hand.

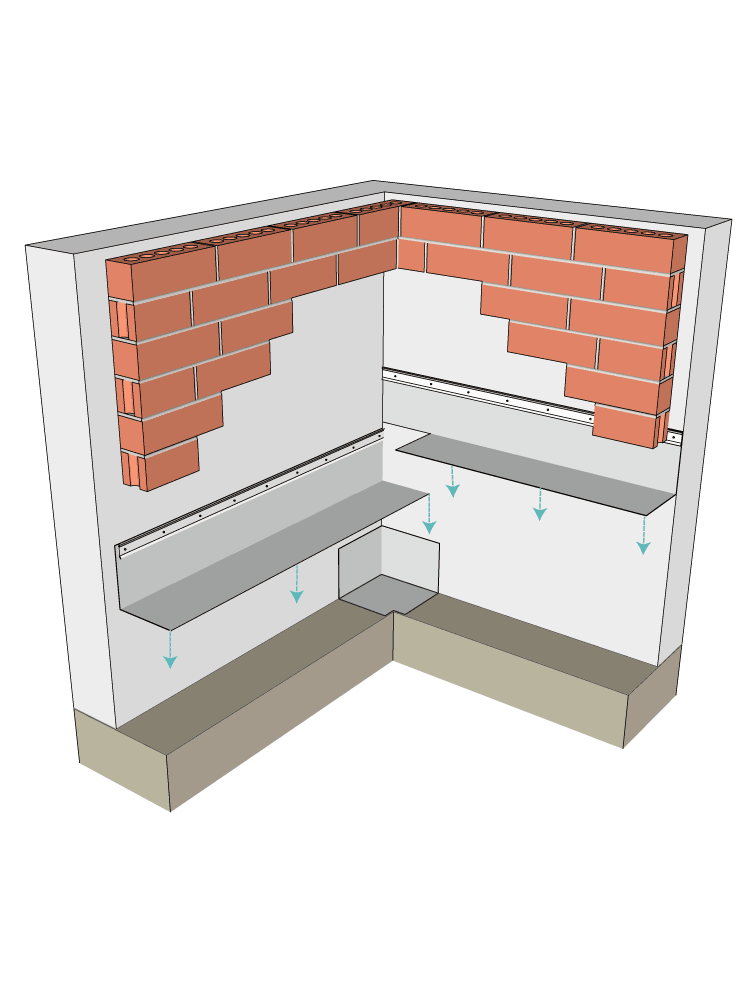

PROSOCO has been at the forefront of supporting Passive House projects nationwide, delivering air- and water-resistive barrier systems, airtightness solutions, and high-performance building envelope products that help designers and contractors meet—or surpass—these demanding standards. From large-scale affordable housing developments to innovative institutional buildings, our products have played a role in some of the most successful Passive House projects in the country.

Explore our case studies to see how PROSOCO has partnered with teams to bring Passive House visions to life:

The Air Barrier of the 34-Story Sendero Verde Passive House

Delivering airtightness on one of the largest fully affordable Passive House developments in the world.

New Design for an Old Dairy

Transforming a historic structure into a modern Passive House building.

Multiple Wins for Multifamily

Affordable housing that sets the bar for performance.

The Bullitt Center and PROSOCO

Contributing to one of the greenest commercial buildings in the world.

Autoclaved Aerated Concrete: One Passive House Builder’s Perspective

Innovative materials for high-performance, energy-efficient design.

The Accidental Passive House

A project that exceeded efficiency goals by design.

With the growing number of Massachusetts communities adopting the opt-in energy code, the future of high-performance, energy-efficient living is here—and PROSOCO is ready to help you build it.

![]()

Customers prefer these R-Guard products for Passive House projects