A project with 34 stories and a goal of Passive House certification has to pay special attention to air-sealing their building envelope in order to hit the PH air-tightness target of 0.6 ACH50.

We recently got to take a look inside the in-progress construction of Sendero Verde's tower, dubbed Sendero A, and get an up-close look at their building envelope as it was being built.

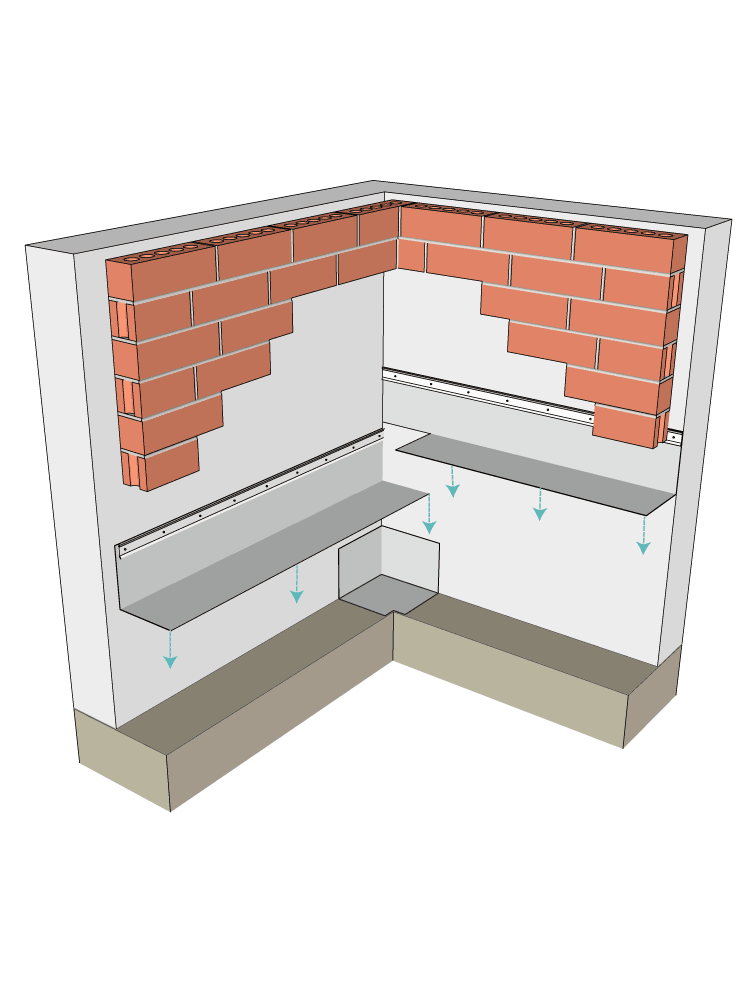

Here's what the air-sealing process at the rough opening looks like:

The development spans an entire city block, from 111th Street to 112th Street and from Park Avenue to Madison Avenue. It consists of two phases (phase one is already completed, occupied, and Passive House certified!) with the second phase's high-rise corner tower rising 34 stories into the New York City sky.

Sendero Verde was designed to be energy-efficient and environmentally sustainable, so the building envelope was constructed using a variety of techniques and materials to reduce energy consumption and improve indoor comfort. Here are some of the features of the building envelope:

Insulation

The building envelope includes insulation in the walls, roof, and floors to reduce heat loss and gain. The insulation used in Sendero Verde is made from recycled materials and has a high R-value, which indicates its effectiveness in preventing heat transfer.

Windows

As with most Passive House structures, high-performance windows are used in the building to reduce heat loss and gain. These windows have multiple panes of glass, low-E coatings, and gas fills to improve their insulation and energy efficiency.

Air-sealing

The building envelope is designed to be airtight to prevent air leaks and reduce energy loss. This is achieved through the use of air barriers and sealants.

Ventilation

The building envelope is also designed to provide adequate ventilation to maintain indoor air quality and prevent moisture buildup. The ventilation system in Sendero Verde is designed to be energy-efficient and includes heat recovery ventilation to capture and reuse heat from exhaust air.

Roof

The roof of Sendero Verde is designed to be a "green roof," which means it is covered with vegetation and soil to provide insulation, absorb rainwater, and reduce the urban heat island effect.

As I mentioned earlier, Sendero A employs triple-glaze, high-efficiency windows, 728 of them in fact. The project team also chose PROSOCO's R-Guard air barrier system to prevent air leaks and energy loss between the high-efficiency windows and the rough opening.

You can see in the video above that the crew is using PROSOCO's R-Guard FastFlash in the rough opening. To increase speed and efficiency, they were using the roller-grade FastFlash in combination with gun-grade FastFlash. (Gun-grade in the corners and interfaces, roller-grade on the inner and outer face of the rough opening).

After the sheathing was up, Spray Wrap MVP was applied on the field of the wall.

For their critical through-wall flashing, the crew installed PROSOCO's SS Thru-Wall flashing.

When it's completed, the Sendero Verde complex will be the largest fully affordable Passive House building in the world. The complex also features a large community center and a commercial space that will be occupied by a grocery store. The community center features a fitness center, a computer lab, and a large multi-purpose room that can be used for classes and events.

Overall, Sendero Verde is an impressive development that not only provides much-needed affordable housing but also fosters a sense of community and promotes sustainability. It's a great example of how affordable housing can be beautiful, functional, and sustainable at the same time.