Learn why it’s so popular, how it’s made and what product is best suited to densify it.

The use of type 1L cement, also known as Portland limestone cement, has skyrocketed in the last few years, according to Bruce Ferrell, Concrete Flooring Specialist for PROSOCO. Why is it becoming so common? The answer has to do with the process of cement production and its impact on the environment.

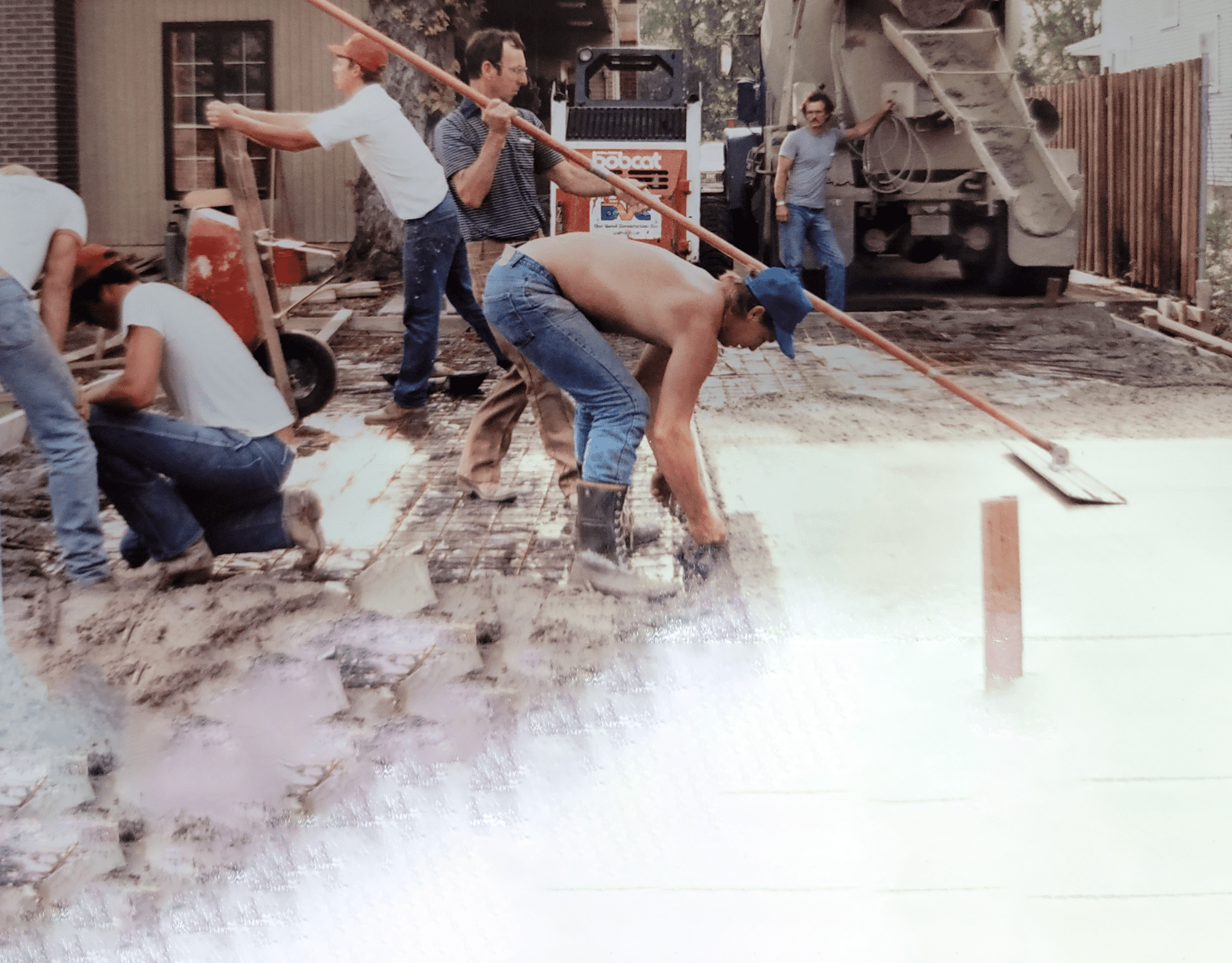

“Type 1L cement was introduced as a way to capture CO2 emissions,” Ferrell says. “Some sources state that anywhere from 7 to 8% of the CO2 generated in the world is during the production of cement. Type 1L was conceived as a way to limit the amount of CO2 generated because cement is basically limestone put in a kiln and cooked. It’s cooked until it turns into little boulders called clinkers, and then they grind it. When that comes out of the bottom of the grinder, it’s called cement.”

The process of cooking and grinding up the limestone to produce cement is not energy-efficient. As a way to reduce the emissions created during this process, the concept of type 1L cement was born. Type 1L cement is mixed with uncooked, or raw, limestone as a substitute for cooked limestone.

Read us in Green Building & Design!

Essentially, the more uncooked limestone in the mix, the fewer CO2 emissions generated during production. In the case of type 1L cement, up to 15% of Portland cement can be substituted with raw limestone.

Many cement producers are switching production to type 1L cement, and once a cement plant starts producing this type of cement, it’s not likely they’ll go back to making traditional cement types such as type 1 or type 2. The reason for this is that producers store cement in large silos that can only contain one type of cement, and the purchase of additional storage silos can be prohibitively expensive.

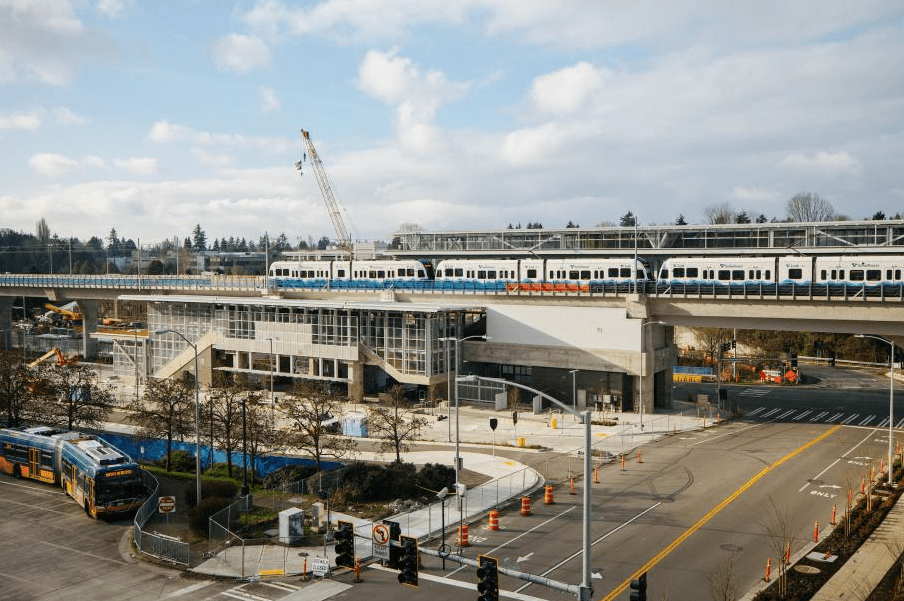

As more and more producers have altered their operations to produce type 1L, ready-mix concrete producers are following suit – which is one reason why type 1L has become so common in a relatively short amount of time in the building materials world.

According to the Portland Cement Association, around 60% of cement in the market today is now type 1L, and Ferrell says it’s getting harder and harder to find type 1 and type 2 cements. That trend is not likely to reverse anytime soon. Today’s type 1L currently can contain anywhere from 5 to 15% raw limestone, but the eventual goal is to bump that percentage up to 30%.

No matter the exact percentage of raw limestone in Type 1L, concrete containing this type of cement reacts differently than Type 1 and Type 2 cements, which requires adjustments when it comes to the placement of concrete as well as the application of chemicals.

How can I tell how much raw limestone is in my cement?

To the naked eye, of course it’s impossible to tell what percentage of uncooked limestone is in your type 1L cement. The only way to know for sure is to ask for a batch sheet from the ready-mix plant to see the exact percentage of raw limestone in your mix. Another factor causing inconsistency in type 1L cement mixes is that across the country, there are three distinct types of limestones quarried from three different deposits. As a result, the cement arriving on any given job site could contain distinct chemistries and reactions to products used to densify and polish concrete.

What's the best product to densify Type 1L cement?

As new technologies, environmental trends and materials develop, extensive testing is essential to understand the best products to effectively do the job needed and minimize the risk of damage. While the industry is still working to understand the implications of type 1L cement in concrete placement, polishing and care, PROSOCO has applied its world-famous testing and research capabilities to understand the new material and how to best densify it. Building material chemists at PROSOCO have determined that PROSOCO's family of blended densifiers is ideal for concrete made with type 1L cement.

That's great news for owners and contractors, because both BD1 and Blended Densifier are among some of the most economical densifier options on the market today. Which is best for you to use? BD1 is a great choice for economical considerations, and Blended Densifier is a more concentrated formulation. They both offer similar qualities, but the main differences are:

Blended Densifier is verified to meet a number of green certifications and credentials, including LEED, SCS Indoor Advantage Gold, and the Living Building Challenge Red List.

If you have any questions, you can always ask your PROSOCO rep or call our Customer Care team at 800-255-4255. We’re real people who answer the phone M-F, 8a-5p Central Time.

![]()