Meet the contractor who has exploded into the NYC masonry scene.

Growing up in New Jersey, Brett Steinberg, owner of King Contracting, had “the best life,” he says. “I had two of everything.”

That all changed for Steinberg at age 14, when his Father unfortunately passed away. While grieving the premature loss of a parent, things took an even grimmer turn for Steinberg when a family debacle created an unforgettable loss of his Father’s business. Everything was basically taken away.

“The plan was to go to college and play D1 ice hockey, but everything doesn’t always go as planned,” he says.

True, Steinberg, 31, could not have possibly imagined where he would end up as a young adult, from his clerical start in construction and his relentless ambitions to build a reputation as “the guy” wanted on masonry jobs across all five NYC boroughs, to the business he started just three years ago that’s approaching nine figures in annual sales. Today, that’s Steinberg’s reality, and he shows no signs of stopping or slowing down.

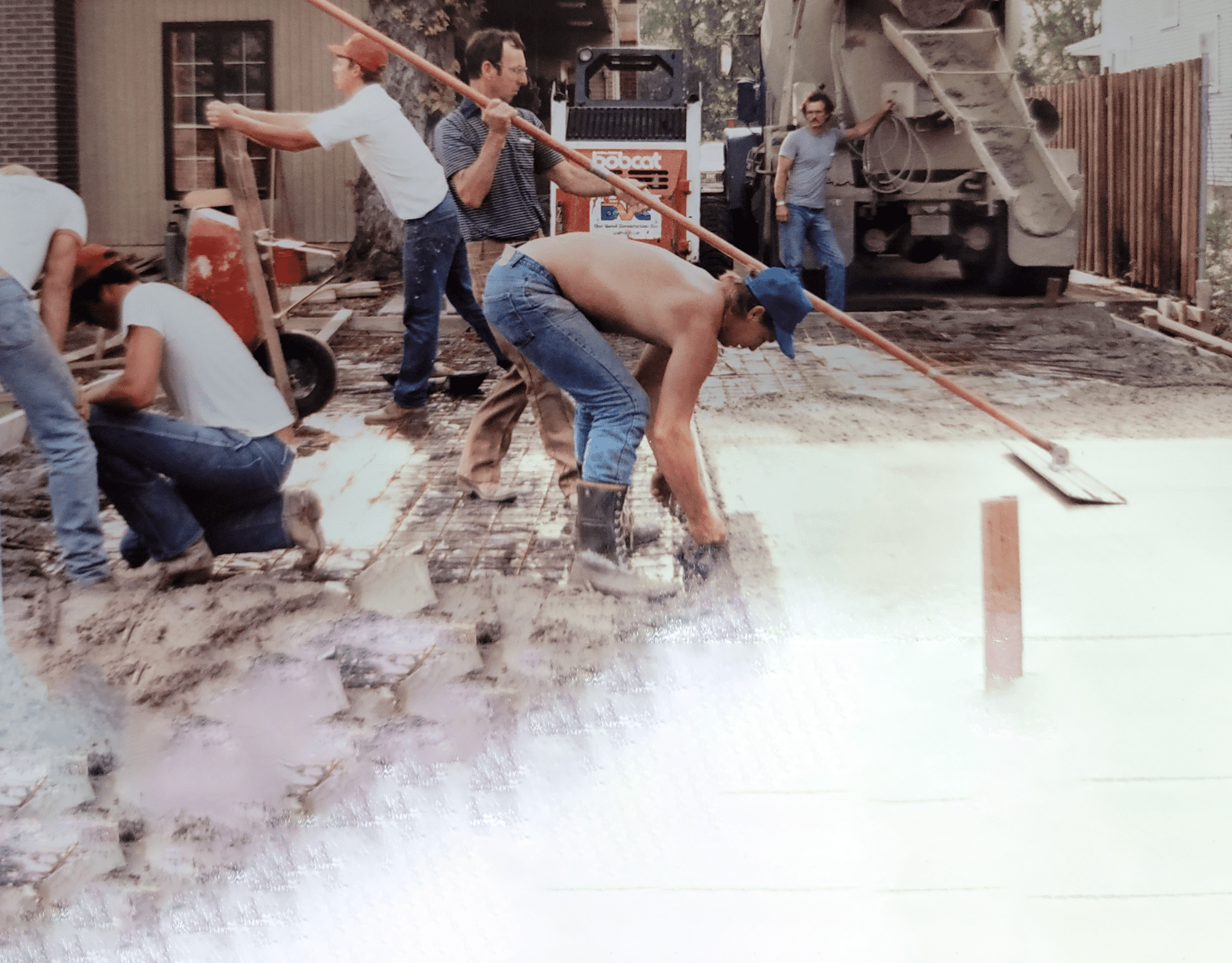

A modest foray into masonry

In spite of an upbringing marred by tragedy, Steinberg did his best to keep his chin up and his body busy in his teen years. At age 17, he found a summer job scanning papers for an exterior restoration company in Manhattan. He did well enough at the task to earn the same gig the following summer. The summer after he graduated high school in 2010, Steinberg took on a full-time position at the same firm, this time doing administrative work.

In just three years, he worked his way up to Project Manager for all Local Law 11 projects in Class A buildings in Manhattan. (Local Law 11 is also known as the Façade Inspection Safety Program, which requires New York City buildings with more than six stories to be inspected for safety every five years.)

Here, Steinberg came to really understand what building in the city was all about. The culture, the lifestyle, the pace – it hooked Steinberg immediately and for good.

“The first office that I worked in had an unmatched, high-energy, loud-yelling type of vibe that always kept other employees and myself on our toes,” he says. “My first boss always had nice clothes, nice watches, nice cars, which made me even more intrigued. But truth be told, I always loved being a part of big challenges with rewarding outcomes. And that’s what masonry is. There are small-scale projects and large-scale projects that come with complexities and challenges. I enjoy taking these on and seeing the finished product come to life. The thrill of this industry really made me want to stay in it and make a career out of it. I always tell others entering this industry that they can create a fruitful and prosperous career, so long as they can withstand the ups, downs, lefts and rights.”

When Steinberg left that firm to work for Rising Sun Construction, he was employee No. 2 after the owner himself. He went from a bustling Manhattan office to a basement office in Elizabeth, N.J., with no true field employees – which, as it turns out, was the perfect environment for Steinberg to prove what he could make of himself and demonstrate his belief in persistence over knowledge.

“I researched the largest potential clients and within six months, I brought in more than $10 million worth of private masonry work in New York City,” he says.

“It was then and there that I taught myself how to estimate and buyout the projects. I always believed that if I wanted to be the best, I had to be capable to be the best in the room when sitting down to negotiate a project.”

Although he didn’t know it yet, people were taking notice of Steinberg’s grit and drive. They admired the way he would unapologetically ask for not just this one job, but all 10 jobs. How he always seemed to be working, from early mornings until 10 at night. And they realized their projects just seemed to go better when Steinberg was involved. Which paid off dearly for Steinberg when it really mattered.

On a roofing project around 2013 in Peekskill, N.Y., for Rising Sun Construction, Steinberg struck up a conversation with the mason on the job and asked him to work for Rising Sun as a subcontractor.

“The subcontractor was absolutely crushing the project we gave him, and the same client began giving me job after job after job,” Steinberg says. “Rising Sun continued to subcontract the work to the same company. After maybe five or six projects with the subcontractor and the CM, I sat down the owner of the masonry subcontracting firm and asked what it would take that he only do our work. He presented his offer, which I then took back to the owner of Rising Sun and he went for it. At this point, I was only an employee of Rising Sun, but had become known as the face of the business.”

Surprisingly, when everyone sat down at the table to sign the contract, the subcontractor told the owner of Rising Sun that unless Steinberg became a partner in Rising Sun, he was backing out of the deal.

“The owner went for it and we all opened up a new company called RSC Group in 2015,” he says. “I ran the day-to-day operations, Frank continued doing all of the work and brought in all his manpower, tools and equipment, and I continued to bring in all of the work year after year. In seven years, we probably completed close to $200 million worth of masonry and roofing work collectively.”

Leading a new venture

Eventually, the partners’ visions veered in different directions, and Steinberg left to start his own company – King Contracting. It wasn’t a solo venture.

Project management followed him to King Contracting, as did supervisors, labor, and, most importantly, clients.

“It showed that the last seven years of my career, working day and night, was worth it,” he says. “In just three years at King, I’ve built a team of nearly 15 project managers, three professional engineers, 20 project superintendents, 5 safety managers and a labor force of more than 800 men. We currently run 15 to 20 projects at a time with another 15 to 20 to start. I’ve set King up to work with the same 5 or 6 repeat clients who are the top of the top, year after year. We became very selective of who we will work with because there are only a handful of clients that understand the prime and sub are on the same team sharing the same end goal – a safe and successful project.”

"I always believed that if I wanted to be the best, I had to be capable to be the best in the room when sitting down to negotiate a project.”

If those numbers sound staggering for a 3-year-old company, you’re right. But they’re no exaggeration. Kevin Miller, independent sales representative at Building & Restoration Technology in New York City, an independent manufacturer’s representative for PROSOCO, sees Steinberg’s forces out in the field every day.

“The amount of manpower Brett can provide is unparalleled to anyone else in the city right now,” Miller says. “It’s not just a lot of guys, it’s an army. He brings different crews to different jobs, and he’ll have 4 or 5 crews of 50 men on one job. When you have that many guys, it’s a force to be reckoned with. Everybody’s short on labor but Brett. The GCs love him.”

The meteoric growth of King Contracting, fueled by Steinberg, is something Miller has simply never seen before.

“He’s the largest tradesman in the city,” he says. “He’s the largest employer of masonry employees. I know of other companies that might have a couple hundred guys. I think he’s the fastest growing I’ve ever seen since I’ve been doing this. He’s really good at doing takeoffs and negotiating with people.”

Miller believes Steinberg’s success is anything but random.

“I don’t think Brett ever is not working,” Miller says. “Even when he’s not in the office he’s doing something for the business. He just works his butt off.”

Steinberg won’t argue with that point. He says the biggest challenge of his job is finding the time to get everything done that needs to get done in the day. “My daily list consists of 25 to 30 tasks which I cannot get into bed at night without completing. The list has financial tasks like payroll and insurance, bidding tasks to make sure we get out our bids accurately and on time, buyout tasks for ongoing and upcoming projects, and daily tasks that come with being the owner of a company.”

Will Steinberg slow down anytime soon? The outlook is not likely, because slowing down would mean letting go of the part of his job that Steinberg prizes the most.

“The first and foremost favorite part of my job is knowing that all of the several hundreds of individuals that work for King go home safe every day and knowing that I can play a part in making sure they and their families are provided for each and every week,” he says. “Our employees are an extended part of my family.”

“My second favorite part of my job is exceeding my clients’ expectations time and time again. I’ve faced a lot of scrutiny and doubt in my career, especially at a young age doing large-scale projects when people thought I would fall on my face. So, rising up to the occasion, performing at a rapid pace and delivering a top-quality project puts a smile on my clients’ faces and mine.”

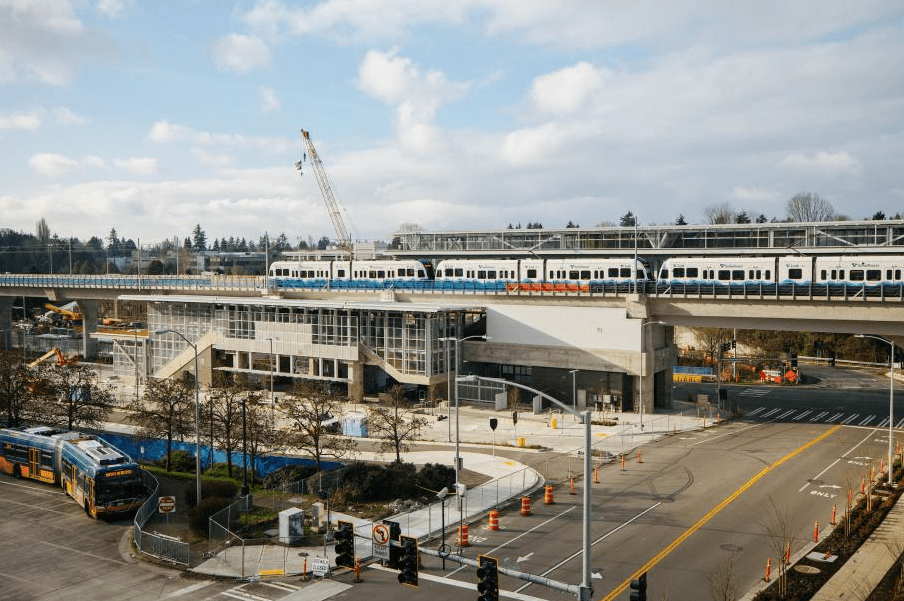

“Sendero Verde’s Tower A was one of those projects that we faced scrutiny and doubt on,” he adds, of the affordable housing Passive House project in Harlem. “Originally, we did not get awarded the project. It came back to us about a year later, with a week to mobilize. We immediately prepared and had more than 100 tradesmen working here at our peak. We accelerated the project and beat the original schedule by nearly three months. We could not have done that without PROSOCO.”

“My third favorite part of my job is closing deals. There is nothing more exhilarating in my life than being at a large conference table with 5 to 10 people reviewing scope, discussing numbers, and shaking hands.”

![]()