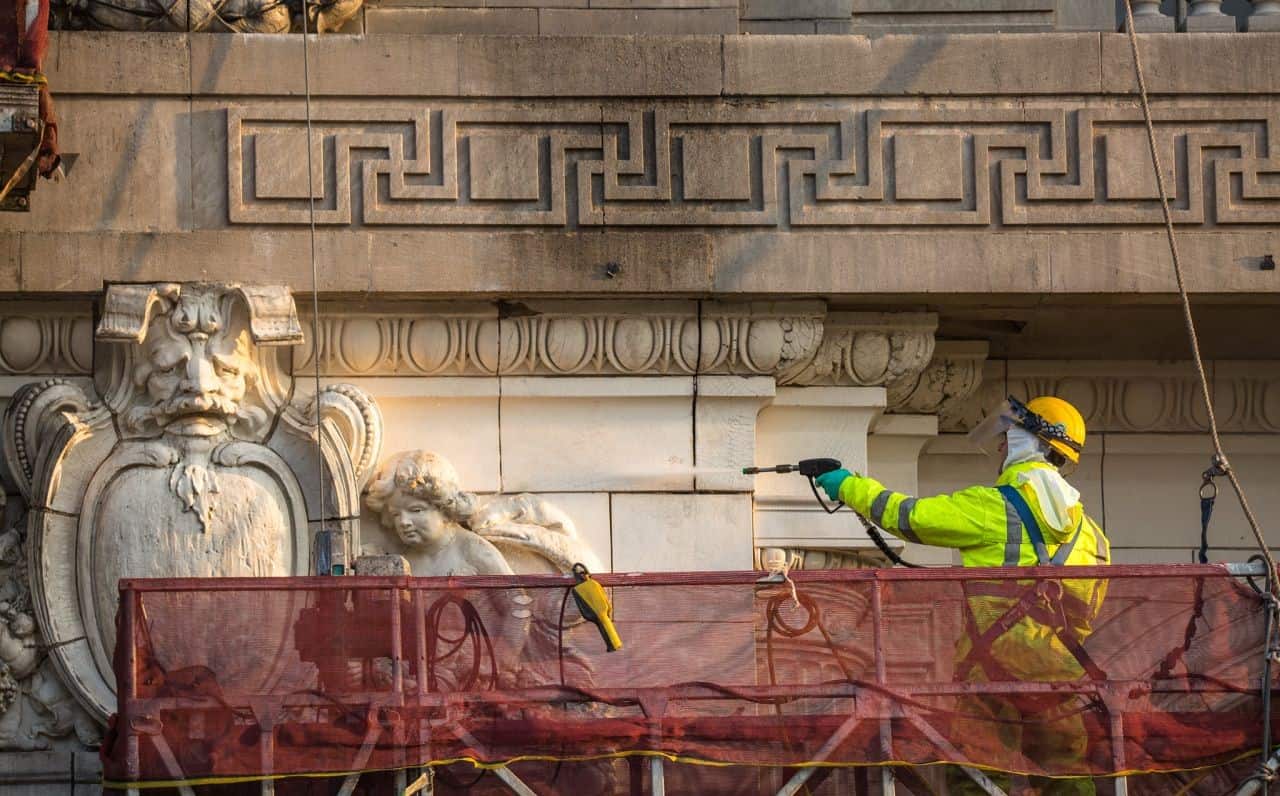

Mason contractors could benefit from entering the growing field of historic preservation. Keep these tips in mind if you’re thinking of doing so.

Historic preservation, or historic restoration, is nowhere near being a new industry, but recent economic trends have some contractors following demand and considering this specialization for the first time ever after years spent exclusively in new construction.

The money is there. According to a recent survey from The Campaign for Historic Trades, the total investment in historic buildings last year was close to $37 billion.

The supply is there too. The survey reported that nearly 2 million commercial buildings, 35 million residential buildings and more than 2 million multi-family structures in the U.S. are at least 50 years old. (Fifty years may seem arbitrary but this number is important because it gives buildings eligibility for listing in the National Register of Historic Places as well as historic tax credits.)

These numbers don’t surprise people who have worked in the field for years, like Sarah Holder, Preservation and Technical Training Specialist for PROSOCO.

“As a discipline, historic preservation has existed for a very long time,” she says. “Its roots in the U.S. are tied to the saving of Mount Vernon in the 1850s and the unsuccessful bid in the 1960s to save New York City’s Penn Station. As a movement, there’s long been advocacy to preserve and retain existing historic building stock.”

“We don’t see a lot of new trends in historic preservation because the mission of that work is always to retain as much of a historic structure as possible while preserving character-defining features that can’t be easily replicated or replaced if they were lost over time,” she continues. “So the changes aren’t so much in preservation, but in the way that the general public sees preservation as a tool for economic development.”

If the prediction holds true that new construction will continue to cool off, the focus will naturally shift to restoring existing buildings and adapting them for a new purpose – what many in the industry refer to as adaptive reuse. One noteworthy example of this is Old Cook County Hospital in Chicago, which was empty for about 40 years and delivered to a project team in completely decrepit condition. The team, including a variety of restoration specialists, rehabilitated the building for a new use – a Hyatt hotel, office spaces and commercial tenants.

These are the three things Holder says every mason contractor should know about historic preservation before entering the business.

1. Material matters.

At face value, the brick on an historic building may look similar to new brick, especially if it’s been well-maintained. While they are both brick in material, they likely differ in other factors that, when misunderstood, can cause damage to an historic building.

As one example, brick manufacturing has changed significantly over the years.

"We went from sun-baked or low-fired brick to modern, controlled brick manufacturing practices. Those changes in the manufacturing of masonry materials must be accounted for in the way the materials are treated."

An historic building was also likely built with a different mortar-pointing material than a contemporary one.

“Let’s say you have a building constructed of low-fired brick in the 1900s, the pointing mortar on this structure would have been soft and compatible to the porous brick,” Holder says. “The pointing mortar on a modern building is going to be much harder due to its use around higher-fired brick and changes in building construction over time. If you use the same strength mortar for both buildings, it could cause damage to the historic structure. The mortar is designed to be a sacrificial element in your façade and be a pathway for water and moisture vapor to escape. Mortar is what connects all your brick or masonry together, and your brick is always supposed to be the harder element. If you use a harder mortar than brick, then your brick becomes the sacrificial element.”

“As people are entering into preservation and historic restoration, especially from a masonry perspective, it’s important to understand those nuances of materials and how construction technology has changed over time. This applies not only to materials, but also to the methods in which we use them. Your repair strategy should be customized accordingly.”

Holder mentioned Old Cook County Hospital as a perfect example of the need for understanding the custom needs of each individual historic building. That project used one of PROSOCO’s restoration cleaners (766 Limestone & Masonry Prewash) and neutralized with Light Duty Concrete Cleaner because there was both atmospheric and iron staining on the masonry. Every job is different and so the restoration approach will differ as well.

New construction contractors may find it useful to know that one of the most important standards to a preservationist is to first, do no harm.

“We don’t want to cause any adverse effects to the building,” Holder says. “We try to preserve as much original material as possible, and any new material that’s installed should do no harm.”

The Hippocratic Oath of preservationists is also a guiding philosophy of PROSOCO. That involves ensuring the best care possible of buildings through products built for specific purposes; testing to ensure satisfactory results without causing damage; and time spent in the field training and educating installers with technical knowledge and demonstrations on how to apply the product correctly.

2. Funding of an historic preservation project may look a little different.

Contractors new to historic preservation might not recognize the way developers and owners fund these projects. Various agencies at the federal, state and even local levels exist exclusively to financially aid the preservation of historic buildings.

One of the most common sources of this type of funding for historic preservation is the Federal Historic Rehabilitation Tax Credit, which can offset the cost of rehabilitating a building by up to 20%. The expenses must qualify as rehabilitation expenditures, and also, because this incentive at the federal level is designed to drive economic development, the only properties eligible for the federal tax credit are income-producing properties, like commercial or multi-family. They also must meet the Secretary of the Interior’s Standards for the Treatment of Historic Properties.

The Federal Historic Rehabilitation Tax Credit has leveraged more than $116 billion in private investment and preserved more than 47,000 historic properties since 1967.

Projects can also combine funding sources, adding to the financial health of a project. Federal incentives and credits can be combined with state ones. In Kansas, for instance, the tax credit is 25% of qualified expenses of a historic restoration.

Financial incentives are working as intended to drive growth in this section of the market.

“Due to the financial incentives and the seemingly never-ending supply of historic structures that need work, we continue to see growth in this area,” Holder says. “We’re also seeing growth among the diversity of contractors. It’s no longer just specialty restoration contractors. There are other types of masonry contractors trying their hand at preserving historic buildings.”

3. Invest in training.

The skilled labor supply has not kept up with this growth in restoration. “As there’s growing interest in historic preservation work, there’s also a growing need for training and development of qualified contractors and craftspeople,” Holder says.

Training events focused on restoration are available from trade organizations like the Mason Contractors Association of America and from programs such as the Maypearl Brick Academy, led by Bob Holmes in Maypearl, Texas.

The bottom line is restoration is a great place to be currently, and for the foreseeable future.

“The large gaps we’re seeing of qualified craftworkers doesn’t take into account the large population of people approaching retirement age that are going to leave an even bigger gap in institutional knowledge,” Holder says. “We have a dwindling rather than growing workforce, and the number of projects is growing, so we don’t have enough skilled workers to meet demand. One piece of advice to contractors who want to be competitive in this area is to invest in training your workforce.”

![]()