A miraculous restoration in Seattle is overcoming painted masonry, water-related deterioration, and collapsed walls from seismic events.

![]()

“The building was almost a ruin," says Matt Aalfs, founding partner of BuildingWork. "It had been unoccupied for many years and was in very bad shape. That’s the best way to describe it."

Aalfs' design firm is running point on an enormous restoration of the historic Metropole building in Seattle. This one-time staple of downtown Seattle was in such bad shape that Aalfs himself says it’s amazing that they're able to save and restore it. Once a renowned drug store and hotel, the structure’s brick exterior had been neglected for decades, and its interior crumbling and decrepit.

In 2019, the Metropole’s future brightened when the Satterberg Foundation purchased it with the goal of transforming it into a mixed-use, community space, including office space, event and conference space, and a child care center. The owners also aspired to meet green standards like LEED Platinum, aspects of the Living Building Challenge and the Seattle 2030 District.

With a restoration team in place (BuildingWork as the architect; WG Clark as the general contractor; and Finishing Touch Masonry as the façade stabilization contractor), work began in 2022 to learn exactly what procedures were needed for restoration, and to what degree of severity.

"(The paint) looked like frosting on a cake. Now that we’ve got it removed, you’re seeing the individual stone, the carvings, and the detail is re-emerged. It’s amazing.”

It was a delicate task for a building of such historic significance. Aalfs explains that the Metropole, built in the 1880s by one of the founders of Seattle itself -- Henry Yesler, is a keystone of the nationally recognized historic district of downtown Seattle. (As a historical anecdote, a road named after Yesler, Yesler Way, is the nation’s first “Skid Row,” adapted from “Skid Road,” and was coined as such during the 1850s timber-harvesting era in the Pacific Northwest.)

“A big part of our project was transforming an unused, vacant, historic building into a mixed-use community resource center, bringing it up to code and meeting LEED Platinum design,” Aalfs says. “It’s really hitting the highest level of sustainable design.”

"We thought we’d lose a lot of the stone surface... due to moisture damage. It’s much better than what we expected. The contractor made some adjustments once we got going, and it’s really been successful.”

The building itself “is a really fascinating stone façade restoration,” he adds. “The main façade is clad in sandstone, and it had been painted for 70 or 80 years. I have no idea when the paint was applied, but the paint had damaged the stone because it traps water.”

Step 1 for the design-build team involved figuring out how to get the paint off, including what method to use while minimizing damage to the historic stone surface.

As of Spring 2023, Aalfs says crews were nearly done with the paint removal portion using PROSOCO’s SafStrip 8.

“We thought we’d lose a lot of the stone surface because there were areas where some of the stone had deteriorated due to moisture damage,” he says. “It was soft, and those areas were retooled, but it’s much better than what we expected. We tried a whole lot of different methods with testing and settled on that method. The contractor made some adjustments once we got going and it’s really been successful.”

A successful paint removal process was a huge win for historic preservation.

“Removing the paint is not something we normally get to do,” he says. “With the contractor, we were able to convince (the owners) that it was the right thing to do, to spend all this money to turn this building into an amazing restoration.”

Why was the paint there in the first place? Aalfs’ theory is simple and takes into account a major earthquake that damaged the building in 1949: “(Painting the walls) was cheaper, faster, and they didn’t really care. After the earthquake, two of the upper floors collapsed. Buildings then weren’t as valuable. Masonry restoration was needed but they just said, ‘Let’s just save money and paint it.’”

Seismic proportions

Damage sustained to the structure from the 1949 earthquake led to another significant component of the Metropole’s restoration.

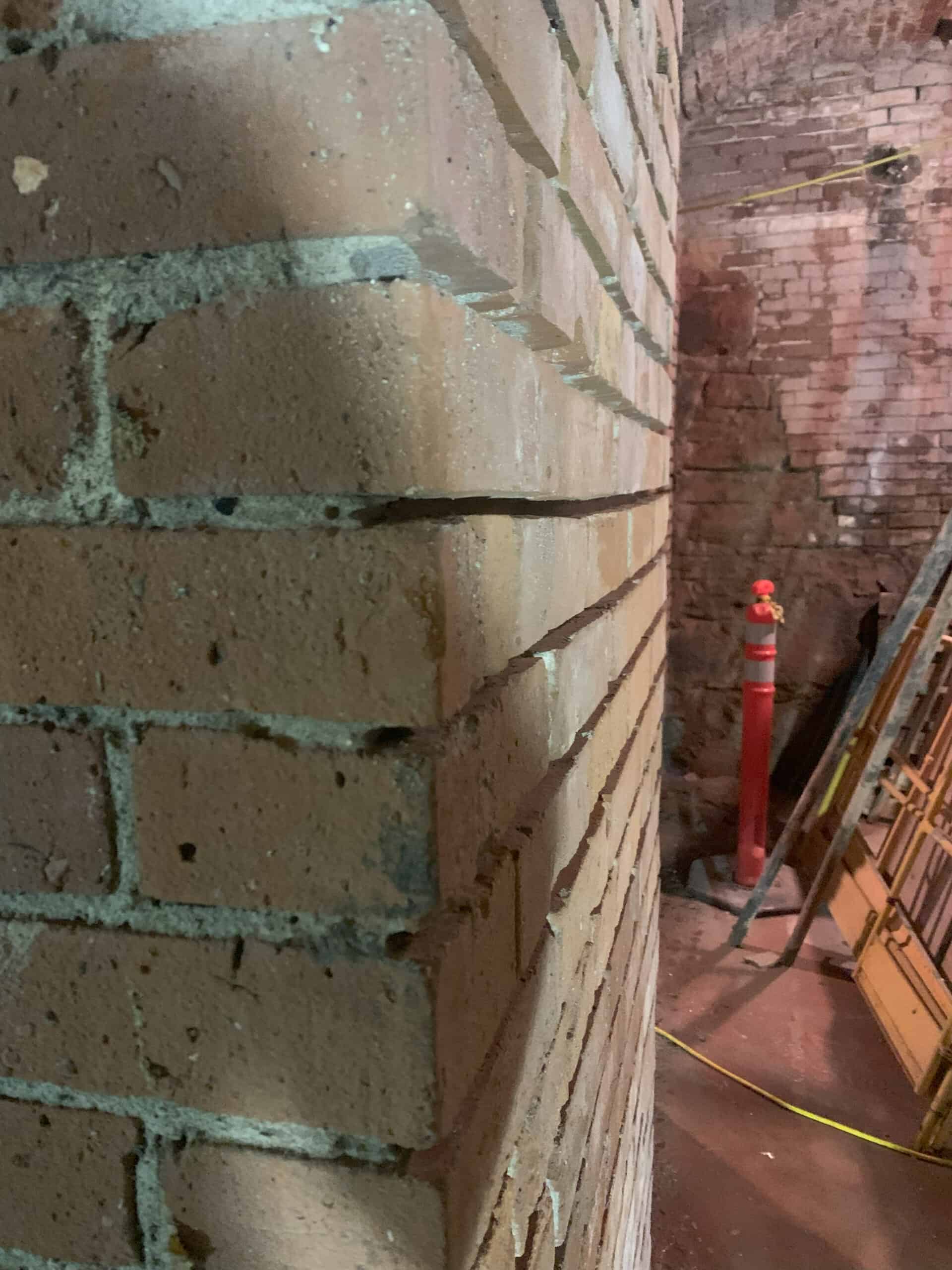

“The structural integrity of the building was in pretty bad shape,” Aalfs says. “We designed a full seismic retrofit revamping the entire structural system of the building to resist earthquakes. We’re renovating the structure and reconstructing the two upper floors on the southern portion that collapsed. Steel moment frames and concrete shear walls were installed in the building to strengthen the brick and stone walls. They can now be secured to a new structure, and the whole building can be brought up to code.”

Artistic renderings of Metropole, courtesy BuildingWork

The process of stabilizing 35,000 square feet of historic brick and sandstone walls of the Metropole included the use of PROSOCO’s Heavy Duty Sock Anchor, commonly used in restoration jobs to strengthen and repair stonework.

Additionally, masonry cleaning was completed with Sure Klean Vana Trol and Light Duty Restoration Cleaner; and the substrates were consolidated and protected with Sure Klean Weather Seal H40.

Additionally, the rough openings were covered with R-Guard FastFlash, a fluid-applied waterproofing membrane that optimizes airtightness in building envelopes.

As the project nears a projected completion date of January 2024, Aalfs continues to be awed by the transformation of the Metropole, especially as layers and layers of paint are removed to reveal beautiful, long-forgotten details.

“It was just covered in gray paint to the point where you couldn’t distinguish the stone,” he says. “It looked like frosting on a cake. Now that we’ve got it removed, you’re seeing the individual stone, the carvings, and the detail is re-emerged. It’s amazing.”

![]()

Watch how the grout-injection sock anchoring system works and see more photos here!