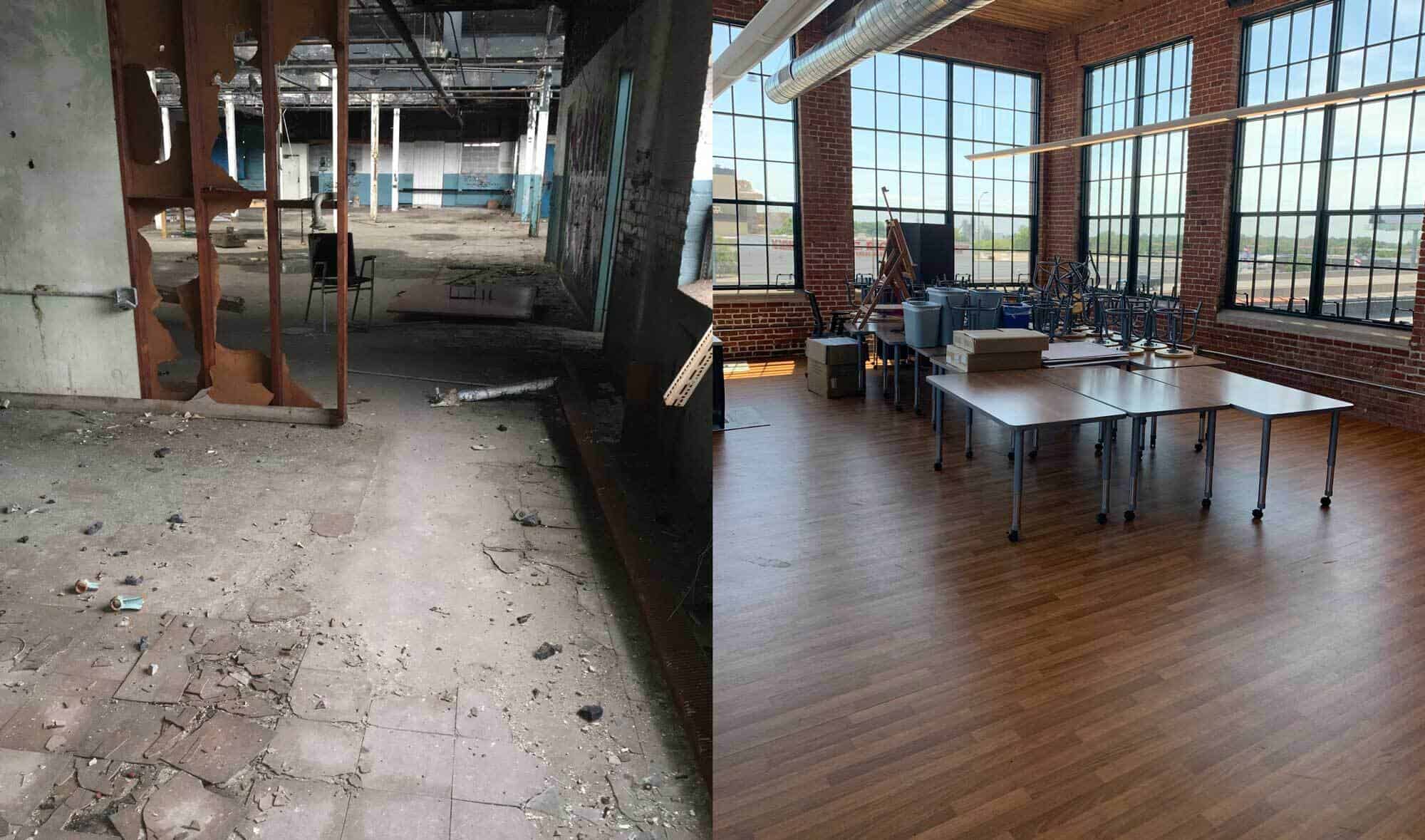

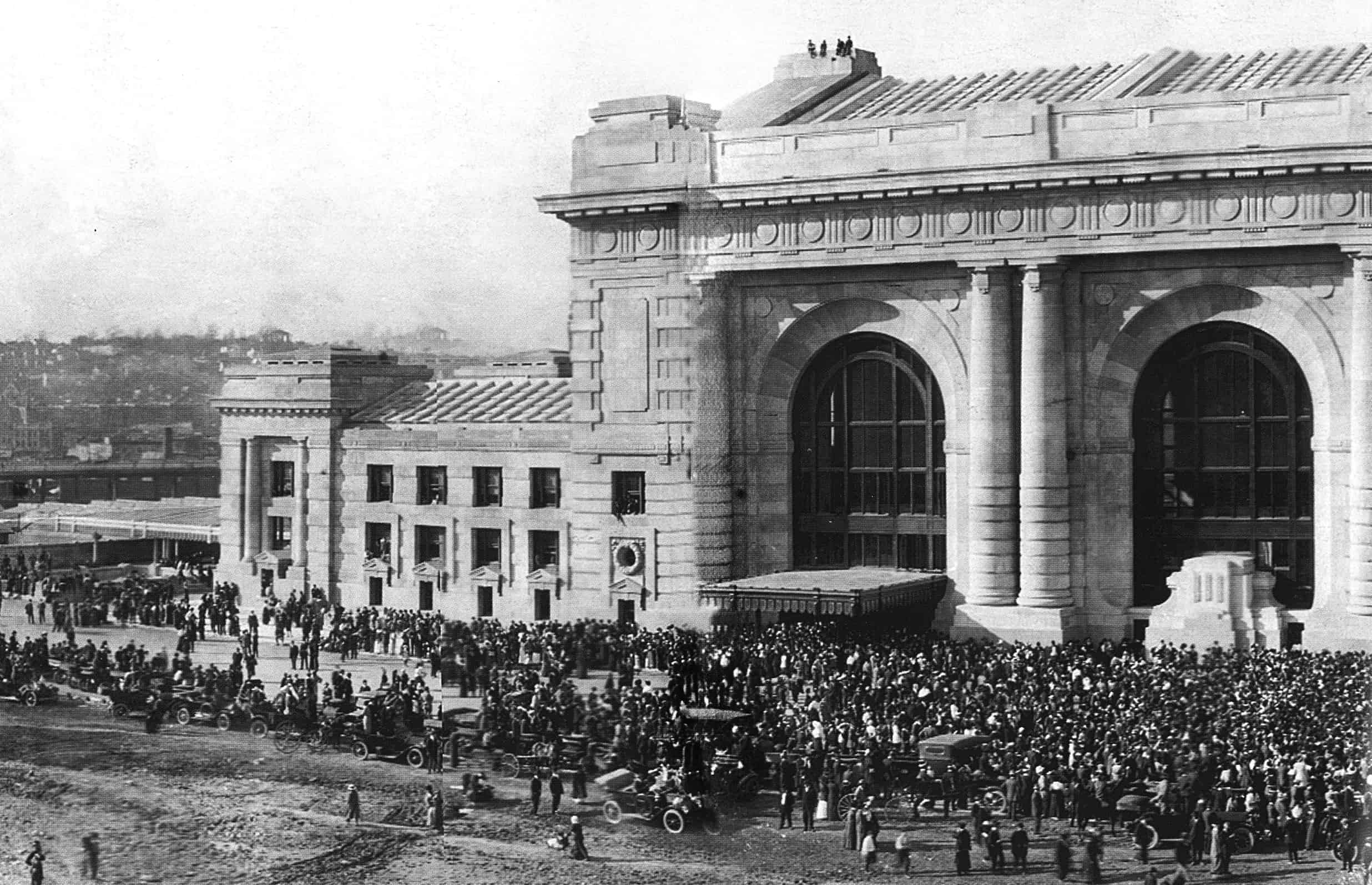

Over the last several decades, we’ve seen a greater appreciation for the renovation of historic buildings as industrial changes over time have necessitated their adaptations into new uses. Adaptive reuse is a much more favorable option than tearing historic architecture down and starting a new build, for many reasons. One positive trend is possible when, during the process of peeling away drywall, plaster and other wall coverings, an incredibly beautiful masonry wall is discovered.

There are many reasons for keeping these walls exposed instead of tearing them down. In addition to being aesthetically stunning, exposed interior masonry can be less costly to keep rather than replace. The exposed masonry can also provide the benefit of performing as a thermal mass wall, storing solar heat energy. These masonry surfaces often lend themselves to picturesque settings, enhancing the authentic feel of a structure, especially in downtown or historic areas.

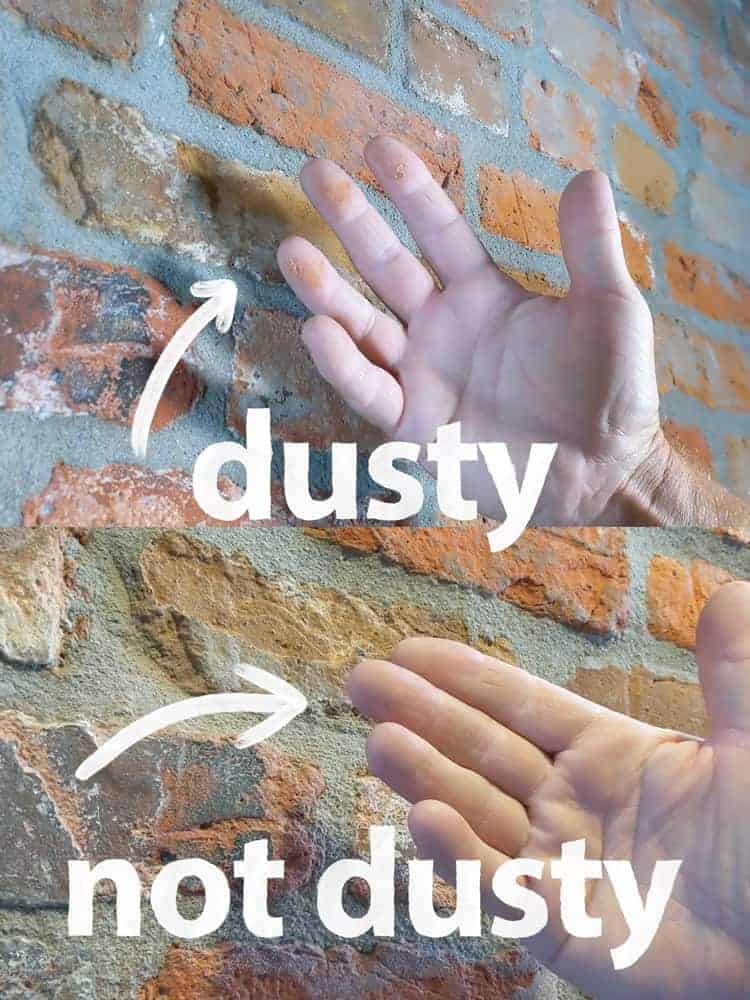

However, over time, the sand and lime mortar binding them together can begin to break down and create a dusting issue when uncovered. This can cause major aesthetic and maintenance challenges and even health concerns. When the walls are first exposed, it’s not uncommon to see a 2-to-3-inch pile of lime and sand dust at the base of the wall, hard evidence of the erosion.

To keep this dust at bay, these masonry walls require dustproofing and protection. The objective is to consolidate the dust and prevent further dust generation while maintaining the walls’ natural ability to breathe, preventing moisture from begin trapped inside. Some contractors might choose an epoxy sealer for this task. However, when epoxy or other film-forming sealers are sprayed onto the walls, they create a shiny finish that can actually detract from the historic look of the masonry—making it look like a cheap, modern-day substitute. Although there are sealers that provide the preferred “aged” matte finish inherent in historic masonry walls, their downside is that they don’t allow the wall to breathe—and trapping water in the walls is a virtual petri dish for efflorescence, mold and other water intrusion issues.

Breaking through the downsides

Designed specifically to solve these challenges, PROSOCO’s unique Interior Masonry Dustproofer is the only product of its class to prevent further dusting of exposed interior masonry surfaces while also leaving a natural matte finish and simplifying the long-term maintenance of interior masonry. In addition to drying to a clear, matte finish, Interior Masonry Dustproofer does not yellow and helps to control efflorescence, mildew and other moisture-related stains. Treated surfaces “breathe” as they did naturally prior to application, rather than trap moisture.

Easy Application

Ready-to-use Interior Masonry Dustproofer is simple to apply. It requires a single application to achieve dustproofing while maintaining the surface’s natural appearance. The product can be sprayed, brushed or rolled on and retains the wall’s natural performance properties.

Preparation involves a broom or vacuum to remove cobwebs, dirt, and loosely bound dust from the surface. No deep cleaning is necessary. Surfaces should be clean, dry, absorbent and free of debris.

Credentials Matter

Anything that deteriorates a building’s indoor air quality or occupant health is a hazard. PROSOCO’s Interior Masonry Dustproofer meets third-party standards for indoor air quality, and also does not contain any of the International Living Future Institute’s “Red List” of chemicals that are known to harm human health and the environment. Low-odor, this product is also VOC-compliant with all national, state and district regulations.

You don’t have to hide masonry walls or remove their beauty

If you’re involved in retrofit, renovation or adaptive reuse projects, it is possible to keep that original wall and its historic look, while also eliminating the headaches and hassle of future erosion and maintenance problems.

The use of environmentally safe Interior Masonry Dustproofer on brick, mortar, natural stone and other porous masonry prevents further dusting, provides water resistance to the applied surface and yields a clear, matte finish while retaining the wall’s natural breathability properties and the environment’s air quality.

![]()