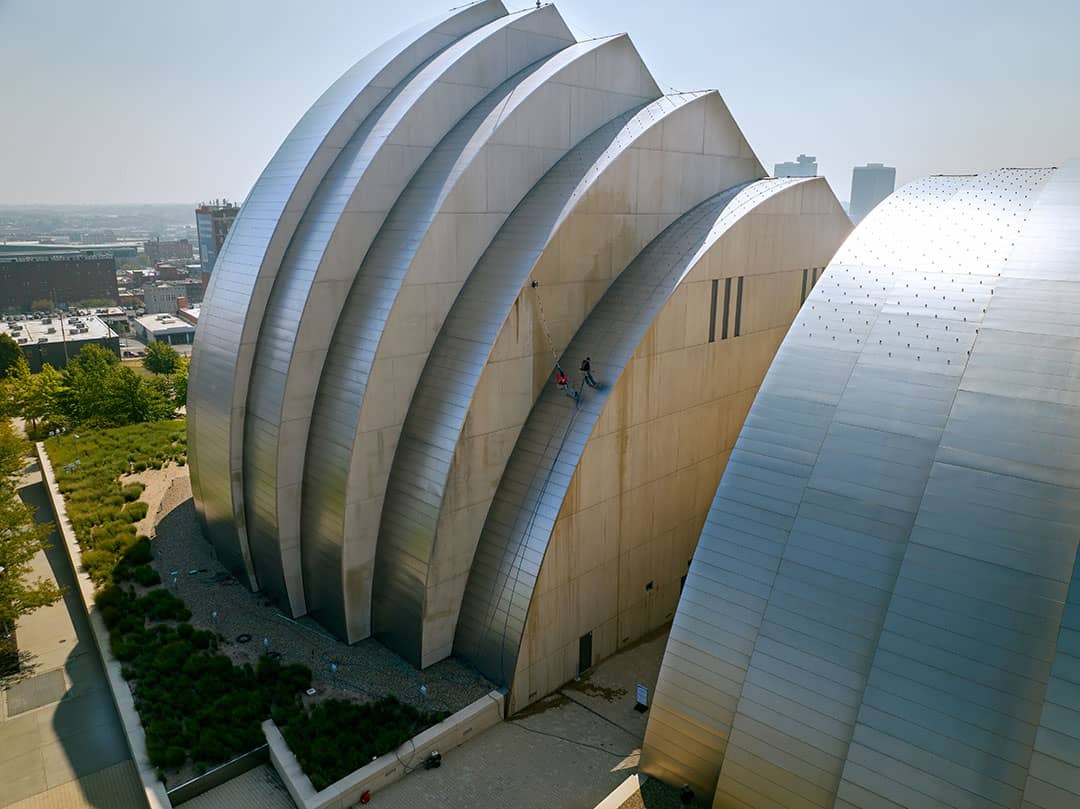

When the Kansas City Chiefs played on Sunday Night Football earlier this year, the TV broadcast featured a shot of the Kauffman Center for the Performing Arts in downtown Kansas City – a nod to the unique beauty and character of the building, which has punctuated the Kansas City skyline since 2011.

The design, a collaboration between Moshe Safdie and Yasuhisa Toyota, features grand, sloping stainless steel "ribs" supported by sections of precast concrete.

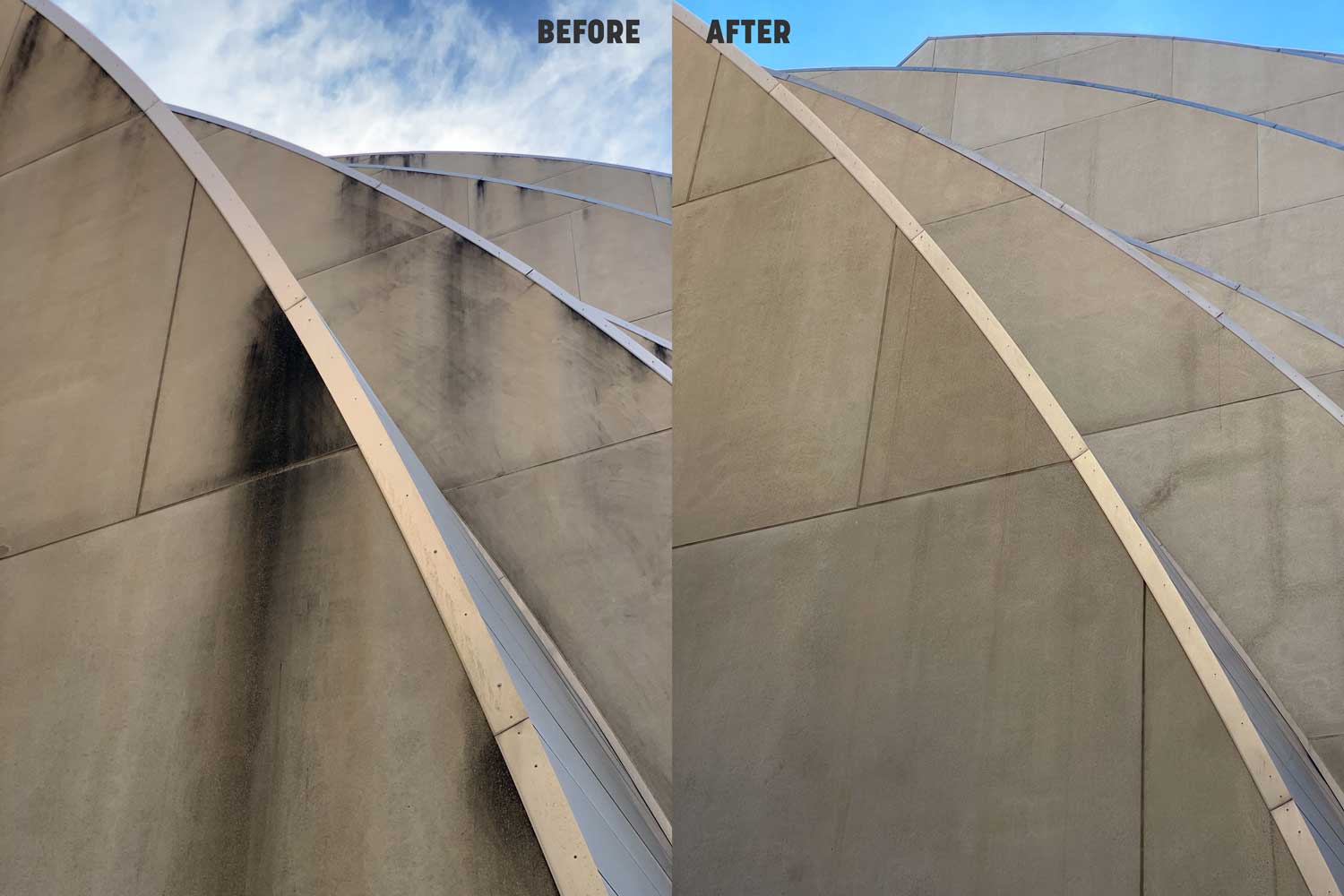

The juxtaposition of these two materials is certainly eye-catching and distinctive, and also a challenge to clean. The project team of a recent cleaning of the concrete knew they needed to carefully select a cleaner to remove the dark streaks staining the precast concrete while not damaging the adjacent metal ribs.

Enter: Mike Dickey of Dickey Sales, a long-time independent rep for PROSOCO. Equipped with several options to test on the concrete, he worked with the team at the Kauffman Center as well as MTB Services to determine the best possible solution to effectively clean the concrete while not causing any damage to the metal.

The cleaner that was found to most effectively remove the biological staining from the concrete while NOT damaging the stainless steel "ribs" was PROSOCO's 2010 All Purpose Cleaner, which is commonly used to remove biological staining from all types of masonry buildings in residential and commercial construction settings, but also is safe to use for household jobs like bathrooms, kitchens, bathtub tiles, and more.

Stevie Douglas, owner of MTB Services, said the mainstay of his business isn't cleaning exterior masonry surfaces.

"Our mainstay is glass, primarily window-washing," Douglas said. "But we can do anything that's difficult to reach up high. When you're up 40 stories, there's not too many people for jobs like that."

Accessing the concrete panels to clean them with 2010 was the next step. "It was a difficult rig," Douglas said.

A quick look at these photos of the cleaning will tell you this was not a conventional rig, or application. His crew repelled down the slopes of the building and used proprietary equipment to power-wash the substrate, apply and scrub the product onto the substrate, and then rinse.

They used a special pressure-washing wand the likes of which Dickey had never before seen, with a spinning head on it.

Douglas, who described the apparatus as "kind of like a lawn mower with a rotating head," said traditional equipment was too heavy for crew members to lift 15 feet above their heads. Instead, they got creative. He found some cheaper alternatives online with plastic discs, took them apart and then customized them by fabricating aluminum reinforcements. Though the original equipment was designed for flat surfaces, Douglas's custom-engineered ingenuity worked.

"Our process was power-wash it first, apply the 2010, let it sit, and then power-wash it again," he said. "The rotating head keeps the concrete uniform as it's cleaned. Without that rotation, we'd get uneven stripes on the panels."

"It was a challenge, and a hard rig, but PROSOCO looks good. This was our second project on that building. A couple years ago we did the east and west elevations and accessed those with big lifts. For the ribs on the north elevation, we rigged it."

They followed up the cleaning with a protective application of SL100.