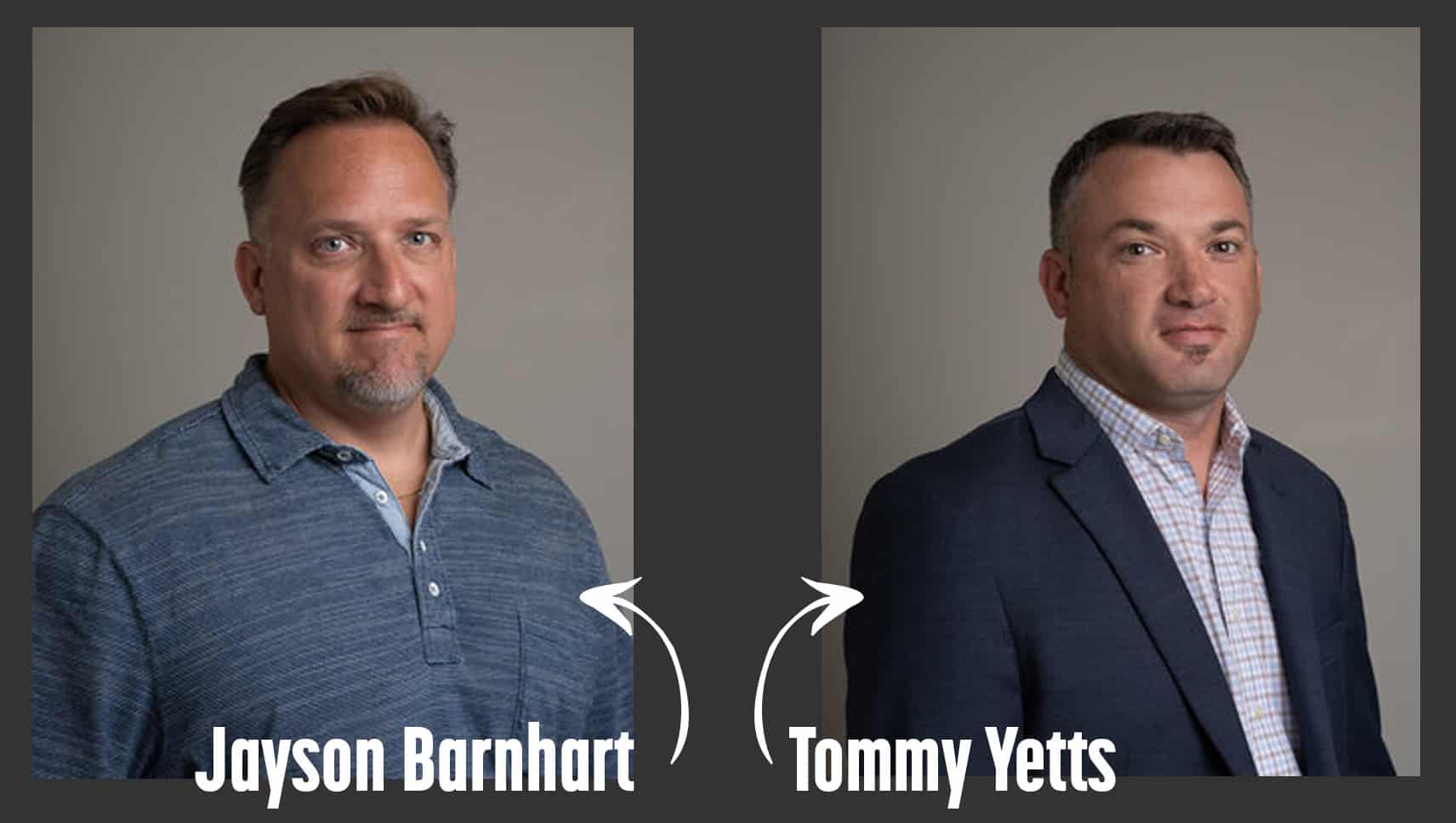

By flying under the radar, Jayson Barnhart and Tommy Yetts have propelled their business to heights unimaginable in 2009.

That’s the year they started Exposed Design Group, a commercial contracting company in Dallas, Texas. Over the last 12 years, they’ve kept their heads down and their sights focused on building a company the right way.

With a marketing budget of virtually nil, they earned a reputation for 1) treating their staff well, including opportunities to grow into leadership positions and provide input from any level; 2) getting their operations to flow, really well; and 3) being honest and valuable partners to clients. Commitment to these principles, in turn, cultivated rapid growth fueled by word-of-mouth alone.

Today, Exposed Design Group, which primarily specializes in concrete and waterproofing work, employs 160 people and counting, is licensed in 14 states and has done work in 40 states. They’ve expanded into other niche services like remediation, floor coverings and coatings, joint fillers, sealers and consulting on building envelope and concrete slab projects. They work out of a 25,000-square-foot facility in Dallas and currently are seeking more space to accommodate their growth – 15,000 more square feet in Dallas and another facility in Houston.

Where it began

The seeds of this business began much earlier than the date of its founding – further back in the 1990s, when Barnhart worked in the caulking and waterproofing industry and got in on the ground floor of Walmart’s switch from VCT tile to concrete.

One employee had an especially entrepreneurial sensibility that stood out to Barnhart, and he didn’t want to let him get away, so to speak.

“I knew (Tommy Yetts) was going to go out and do his own thing and I really wanted to be able to focus on concrete floor projects and I wanted to keep a connection with him. So I partnered with Tommy and that was the beginnings of Exposed.”

“In the beginning, I would say we started out as a waterproofing contractor doing caulking and sealants and industrial floor work. We might do a little spec warehouse floor work. Early on, we were able to get a contract on an Aldi grocery store with an exposed concrete floor. We did a good job on that, and that’s led to a 12-year relationship with Aldi.”

One-time jobs that turned into long-term clients are not a rare thing for Exposed but rather, the majority of its work today. In fact, Barnhart can’t recall a single client that used them only once.

“Our business is relationship-based,” Barnhart says. “I can’t off the top of my head think of anyone we’ve done one project for. Our goal is to build relationships with folks, build trust and make them feel comfortable about hiring us.”

Nurturing those relationships with repeat clients provided direction on other segments of growth for Exposed, as clients turned to them for recommendations on other project needs.

“We’ve had some pretty substantial growth over the years, primarily in those floor scopes,” Barnhart says. “But we’ve also grown in the waterproofing scopes as well. We’ve added the other floor covering scopes when we get a customer saying, ‘Hey, you’re doing this thing, can you give us a number for this related thing?’”

“Tommy and I like to say that everyone starts out as a mom-and-pop. You either stay that way or evolve. That’s one of the things that really sets us apart, is we really focused early on on the procedures and being able to do things the same way, every day, and make what we do scalable.”

Of course, no scalable operation could work as designed or grow as intended without the right people to operate it.

“The hardest thing is finding the quality installers and managers,” Barnhart says. “And especially right now, quality labor is tough to find. We’ve done a good job with that and we’ve got a lot of good teammates.”

With all the emphasis on green building, concrete is here to stay. I think we’re really just at the beginnings of where it’s going to go.

That’s much easier said than done, especially in the Dallas-Fort Worth market, which Barnhart says is one of the most competitive labor markets in the nation. So how do they compete?

“I feel like we’ve done a really good job of retaining employees because we give them opportunities to grow, personally and professionally,” Barnhart says. “There’s no saying, ‘Hey your idea doesn’t matter because you’re only a junior-level estimator.’ Anyone is free to come in and offer an idea or say, ‘Let’s do it this way.’ We let everyone have a say.”

Furthermore, extending trust to their employees and then watching the results is one of the rewarding parts of both Barnhart’s and Yetts’ jobs.

“This is a tough business but it’s very rewarding. Tommy and I are both at a point in our careers and lives where it’s a lot of fun to grow our employees and teammates into leaders. That’s a really fun aspect of where we’re at right now.”

Trends in e-commerce and warehouse floors

Exposed’s ethos that earns repeat clients drew the attention of one notable behemoth of e-commerce, which drives the growth of one of its biggest segments today.

“Our business is definitely heavily weighted in e-commerce and the distribution side of the market,” Barnhart says. “We’ve done over 50 Amazon projects. (E-commerce) is something we feel like we have a real advantage in. We built a good team that’s really familiar with what Amazon and other e-commerce customers expect. I feel like that’s kind of propelled us in that market. We’ve got a reputation that folks know that if we’re on an Amazon or e-commerce project, we don’t have to get trained up on it. We’ve become a valued partner.”

When it comes to finished concrete floors for warehouse clients, the size and scope of the job comes down to the expectations and persuadability of the owner.

“We do a lot of spec warehouse work, where they’re really wanting to save pennies but still want a presentable floor, whereas a lot of the end-user work we do, it’s easy to persuade them it’s worth a few extra pennies to get a higher-quality finished product,” Barnhart says. “One of the things we’ve tried to do over the last three years is to make our process efficient enough that we’re able to shave pennies off what we do, and show the owner or even the spec owner that for a couple pennies more a square foot, we can give you a floor that may set your floor apart, where a client comes in and says we want that building.”

Sometimes the argument of what will save more money in the long-run lands on receptive ears and sometimes not, but Barnhart finds that in either scenario, upfront honesty goes a long way in those conversations with owners.

“We did a large 800,000-square-foot auto parts distributorship where (the owners) were very in tune with what they wanted on the floor and open to suggestions of how we can make this floor better and make the maintenance less intensive. That’s great. Those are the ones you want to work for.”

A lot of times I tell folks that the specs say to start here, and progress to here, and do this, and it doesn’t work that way on concrete.

“We also do a ton of spec work, and that means going in and explaining to them that if you do this, it’s going to add a lot of value to your project that you may not see today, but over the life of this building, you’re going to be thankful you spent a few more pennies a square foot that’s going to benefit you in the long-term. You’re not going to get a majority of them to bite off on that, because of the competitive nature of warehouse work, but you need to offer that and be as transparent as possible. A lot of times, it’s helpful to say, ‘If it were my building, this is what I would do.’”

In the end, the reality is the most competitive, attractive bid will win the job, and usually that does come down to pennies. But Barnhart is always looking for other factors, such as with LS/CS, a concrete densifier/hardener that is popular in warehouse applications due to its dustproofing properties. LS/CS doesn’t require water – which could be a bigger deal than expected.

“There’s a lot of times we’re on floor slabs on projects at a stage where water is a quarter of a mile away. That is a big consideration. It can have a lot to do with water, but we enjoy LS/CS because of the ease of application. I’m bidding a lot of it. I just bid a large LS/CS job today where I felt like we could make that offer and allow them to be a little more competitive.”

Educating commercial clients on finished floors also comes down to the basics sometimes – a reminder of the variation and nuance of concrete.

“One of the biggest hurdles we run into on the front end is, every concrete floor is different,” Barnhart says. “The specifications are not and should not be one size fits all specs. A lot of times I tell folks that the specs say to start here, and progress to here, and do this, and it doesn’t work that way on concrete. Every concrete mix is different, every location is different, and one of the biggest hurdles is getting people to understand that. What we really need to know is what are your expectations. What aggregate exposure do you want, what type of finish do you want? Tell us what you want and we’ll figure out how to get you there.”

A look ahead

Barnhart and Yetts say while it’s been fun to fly under the radar this far, maybe now is the time for a different approach.

“We like to keep our heads down and work hard and let our work speak for itself,” Barnhart says. “But when you get to a certain size like we have, you have to start thinking about continuing to generate the work. 2021 has been a big year for us as far as expanding the marketing and sales side, and that’s probably going to be a big part of next year too.”

What is their vision for the future of Exposed? Barnhart predicts that the concrete flooring and maintenance side will continue to take up a bigger chunk of business.

“With all the emphasis on green building, concrete is here to stay,” he says. “I think we’re really just at the beginnings of where it’s going to go. Exposed or polished concrete in retail facilities has been around for 20 years or so, and we’re still in the early stages. You go into so many chains and outlets where they still have floor coverings. Green building work is going to continue to expand.”

Following the demand of concrete flooring also sets the business up for maintenance work down the road.

“Over the past 12 months, the real driver for us is seeing that we can go out there and provide clients with the training to take care of their floors on their own, and then also keep our foot in the door where there’s going to come a time to rejuvenate the floor. It’s a big part of our business right now and I see that as a huge segment of growth.”

He’d also like to expand into two or three new markets in the next 10 years – growing beyond their current primary markets of Phoenix, Denver and Texas.

No matter how much or how far their business expands, their reason for being will remain -- the gratification of watching something develop, whether it’s a concrete floor or a multi-million-dollar business.

“I love the transformation of taking something and then getting it to a finished product and seeing the real change into a really nice-looking building or nice-looking floor,” Barnhart says. “I think that’s what most people really like about construction is making something from nothing.”

![]()