R-Guard Installation Detail

Open Joint For Low to High Movement Corner Condition Greater than one inch

metal studs with gypsum sheathing/OSB sheathing/plywood

Download this detail

1.

Apply a 3/8-inch bead of SureSpan Adhesive on both sides of the joint. The 3/8-inch bead will spread to a width of 1/2 inch (12-15 mils thick). Sealant coverage may vary depending on the porosity or texture of substrate.

2.

Place the SureSpan EX into the wet sealant using hand pressure to adequately spread the SureSpan Adhesive onto the extrusion, usually squeezing a small amount of SureSpan Adhesive out alongside the extrusion. Small adjustments to the placement of the SureSpan EX may be done at this time, but lifting and re-seating should be avoided and may result in needing additional SureSpan Adhesive installed to fully engage the extrusion into the wet sealant. Use a small roller such as a laminate roller to apply sufficient pressure to set the SureSpan Adhesive.

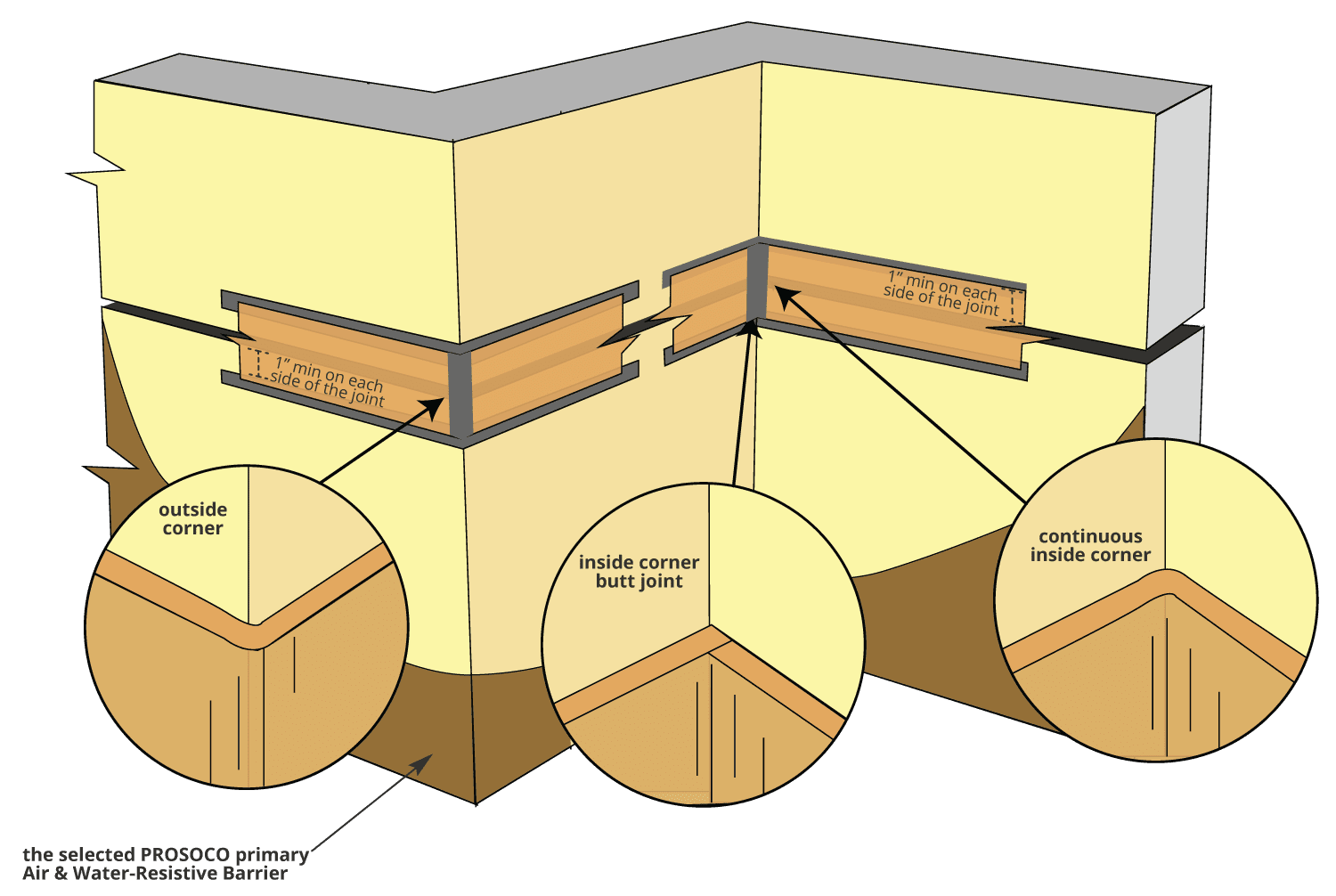

Horizontal joints must be completed before application of vertical joints. Vertical joints should be lapped over the horizontal joint as shown below. If mitered or field-cut corners are used, apply enough sealant under the corner joint so the excess sealant fills the miter joint.

3.

Prior to tooling the excess SureSpan Adhesive alongside the extrusion, shoot an additional 1/4-inch bead of SureSpan Adhesive to smooth out and counterflash the exposed edge of the extrusion 3/4 of an inch. Tool excessive sealant immediately.

Ted Barnekoff

Product Support - Air & Water Barriers

READY TO HELP

At Prosoco, real humans answer the phone, so why not give them a call?