John Montecalvo is on a mission to spread the good news about helical beaming and its ability to minimize life safety hazards and wall restoration costs.

Each year, our national building stock grows one year older and either one year closer to needing repair, or another year overdue for it. Restoration efforts are underway to update a fraction of these buildings; the vast majority remain in need of upgrades – for aesthetic improvements, mitigation of hazardous life safety conditions, or both.

Each year, our national building stock grows one year older and either one year closer to needing repair, or another year overdue for it. Restoration efforts are underway to update a fraction of these buildings; the vast majority remain in need of upgrades – for aesthetic improvements, mitigation of hazardous life safety conditions, or both.

A recent survey from The Campaign for Historic Trades says that close to 2 million commercial buildings, 35 million residential buildings and more than 2 million multi-family structures in the U.S. are more than 50 years old.

Obviously, the biggest priorities for repair are the ones where life safety is a concern. While it’s not incredibly common for chunks of brick and other masonry materials comprising a building’s façade to fall off a building and harm property or worse -- pedestrians, it does happen, and it’s a nightmare of liability for building owners and contractors alike.

Mason contractors, particularly ones specializing in restoration, are likely familiar with some common methods used to repair failing brick facades – such as shoring, needling or removing entire portions of cladding and re-laying courses of brick.

These techniques may be time-tested, but they are also time-intensive. John Montecalvo, technical specialist for PROSOCO’s masonry anchor division, wishes a process called helical beaming was instead the more commonly accepted and utilized method for mason contractors today. That’s because it saves significantly on both time and costs, allowing contractors to reduce life safety hazards and restore our aging building stock at a much quicker pace.

According to Montecalvo’s calculations, replacing a steel lintel and three courses of brick would cost around $195 per lineal foot, and helical beaming applied to the same scenario would cost $70 per lineal foot. Using a traditional method to replace a lintel and brick on a 5-foot window would cost $975, or $350 if you were to employ helical beaming. With a cost savings of more than 50%, why aren’t more contractors choosing this method? It comes down to awareness and education, and Montecalvo is on a mission to reach as many contractors as possible with this application he calls a no-brainer.

What is helical beaming?

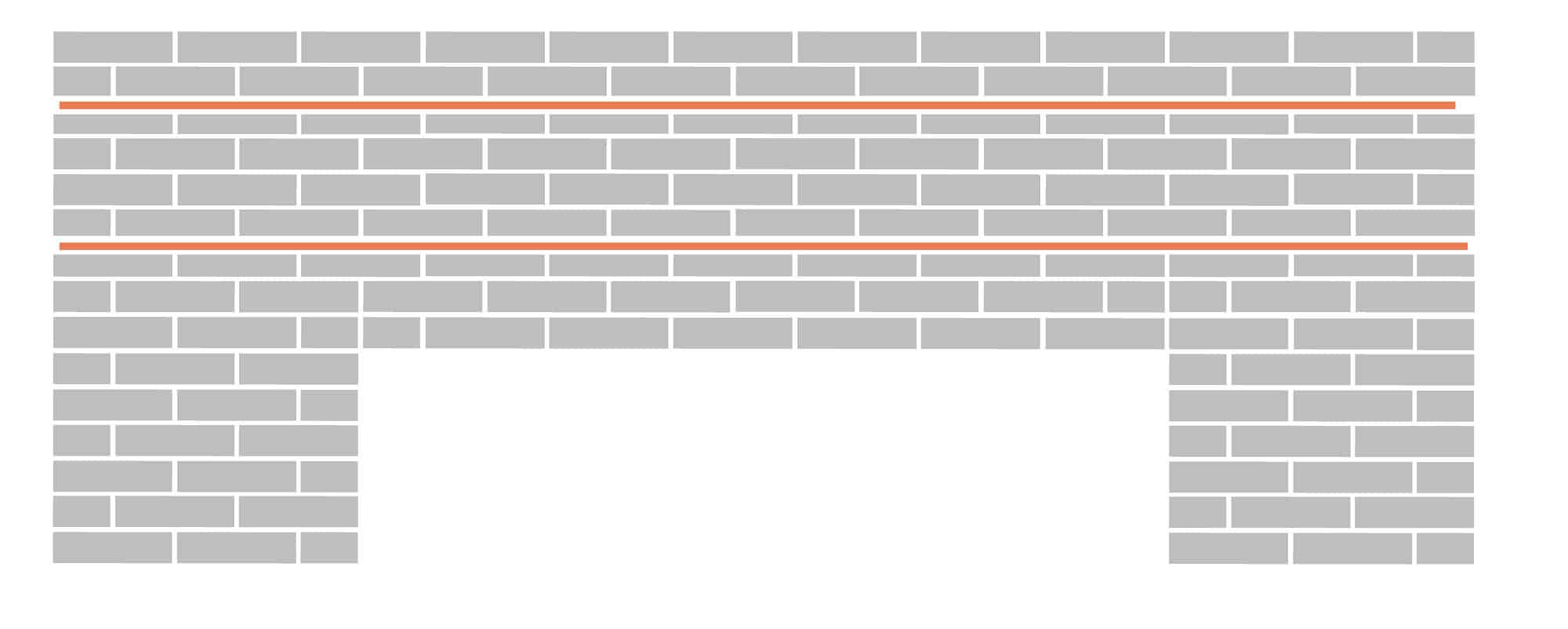

Helical beaming is a technique to restabilize a building’s structure where the masonry has failed and lost some or all of its load-bearing capacity. Appropriate applications could include flashing repair, sagging lintels and lintel replacements. It’s formed by reinforcing two separate lengths of mortar beds with two Stitch-Tie Bars each, embedded in a special type of grout called SureGrout S. The process reinforces areas of masonry to produce composite brick beams, allowing the masonry to span over openings. In multi-wythe construction, helical beaming can provide further strength if installed on both the interior and exterior wythes.

Helical beaming is fully concealed, leaving repairs virtually undetectable post-installation. That’s because the beaming is set back into the joint, allowing the repointing to be done with mortar that matches existing joints in the wall. It’s also a safer method than shoring because it strengthens the wall before existing bricks are removed.

Ready to see the step-by-step instructions for this novel approach, or book a local training?

Learn all this and more in our Helical Beaming Guide.

- Learn how this method can save up to half in your labor and material costs.

- Watch a demo of reinforced versus unreinforced brick.

- See the complete step-by-step instructions.

- Book a training (we bring the wall to you).

- Learn the variety of applications where helical beaming works.