What is a blower door test and why would you need one? Here’s a summary of what you need to know about this performance-based metric for buildings.

What is a blower door test?

A blower door test is a machine used to calculate airflow between the interior and exterior of a structure, measure the airtightness of buildings, and identify spots where air is leaking through a building envelope. This test ensures a certain level of energy performance and is often used when a project team is aiming for a performance-based building standard like Passive House, which requires a blower door test result of less than 0.6 air changes per hour at 50 pascals of pressure (ACH 50).

Blower door test equipment

A blower door machine consists of a fan that can induce various airflows to pressurize and depressurize the building, a tool to measure pressure, and a mount to secure the fan in a rough opening such as a door or window.

What is Passive House?

Passive House is a building standard with extremely rigorous energy performance requirements. Passive House design principles include airtight construction, continuous insulation, minimized thermal bridging, energy recovery ventilation, and solar optimization. This standard mandates a blower door test result of less than 0.6 ACH50.

To learn more about Passive House, visit the Passive House Institute US (PHIUS) website, or the North American Passive House Network (NAPHN) website.

How can R-Guard help me achieve Passive House?

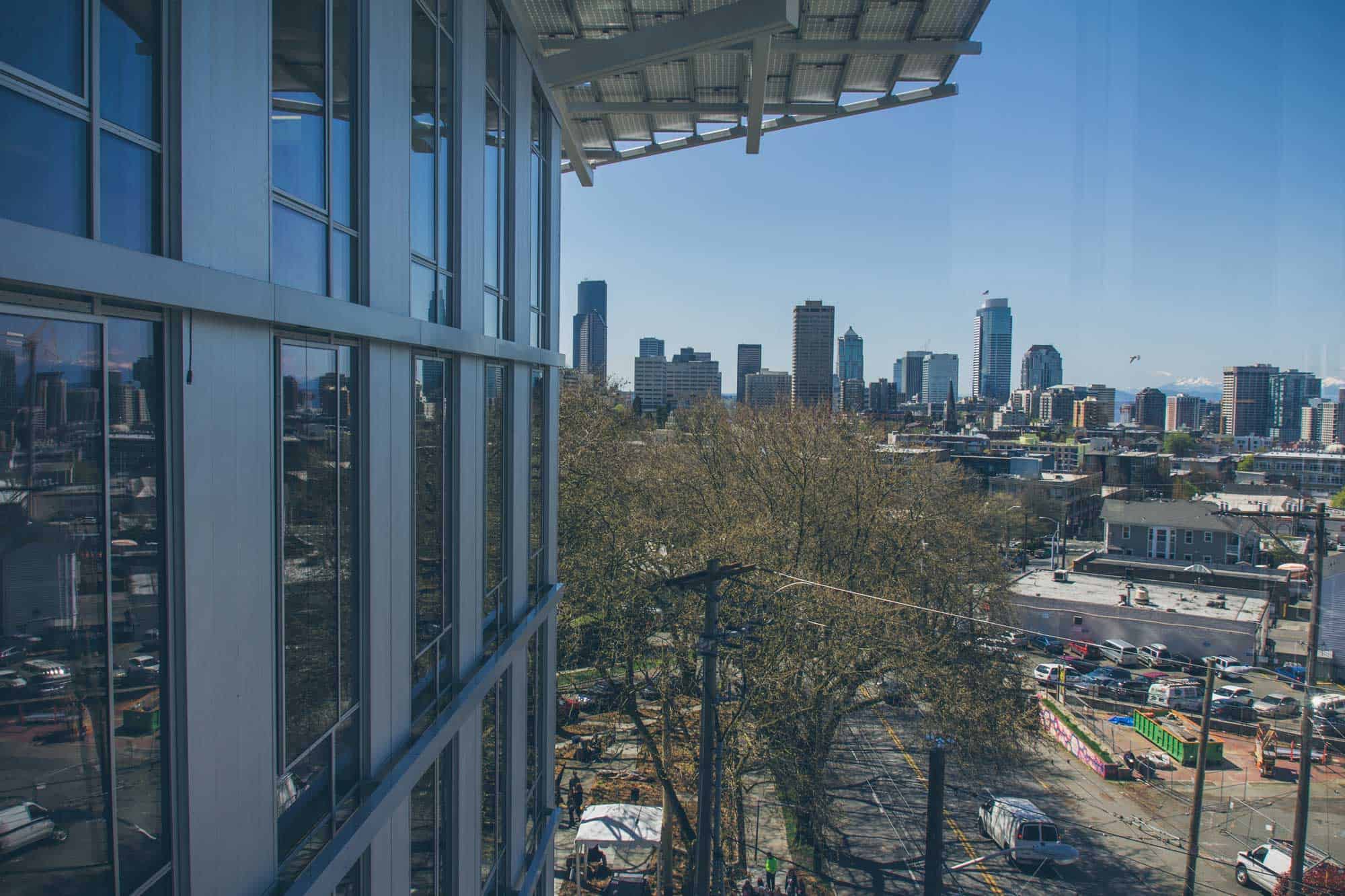

Since becoming the first fluid-applied air barrier on the market nearly 20 years ago, R-Guard air and water barriers have helped myriad construction professionals meet and exceed their energy performance goals, including some of the world’s most ambitious building standards Passive House, Living Building Challenge, and Net Zero. The fluid-applied silyl-terminated polymer (STP) system creates a monolithic barrier that keeps air and water out, but is also permeable to allow buildings to breathe. The combination of R-Guard advantages promotes enduring performance even during building movement and changing climate conditions.

Is R-Guard difficult to install?

The R-Guard system was first designed by contractors who needed a top-performing air and water barrier, and ease of application was one of the most important traits they required.

Their list of traits quickly grew to include 13 product attributes, including the ability to save time, adhere to different materials without a primer, and be immediately waterproof.

The result of this “wish list” is the R-Guard system of products, including Joint & Seam Filler, FastFlash, Cat 5 and AirDam. This system can be installed in less time and contributes to greater long-term energy efficiency than alternative products. R-Guard products also adhere to almost all types of construction materials, simplifying the installation process.

![]()