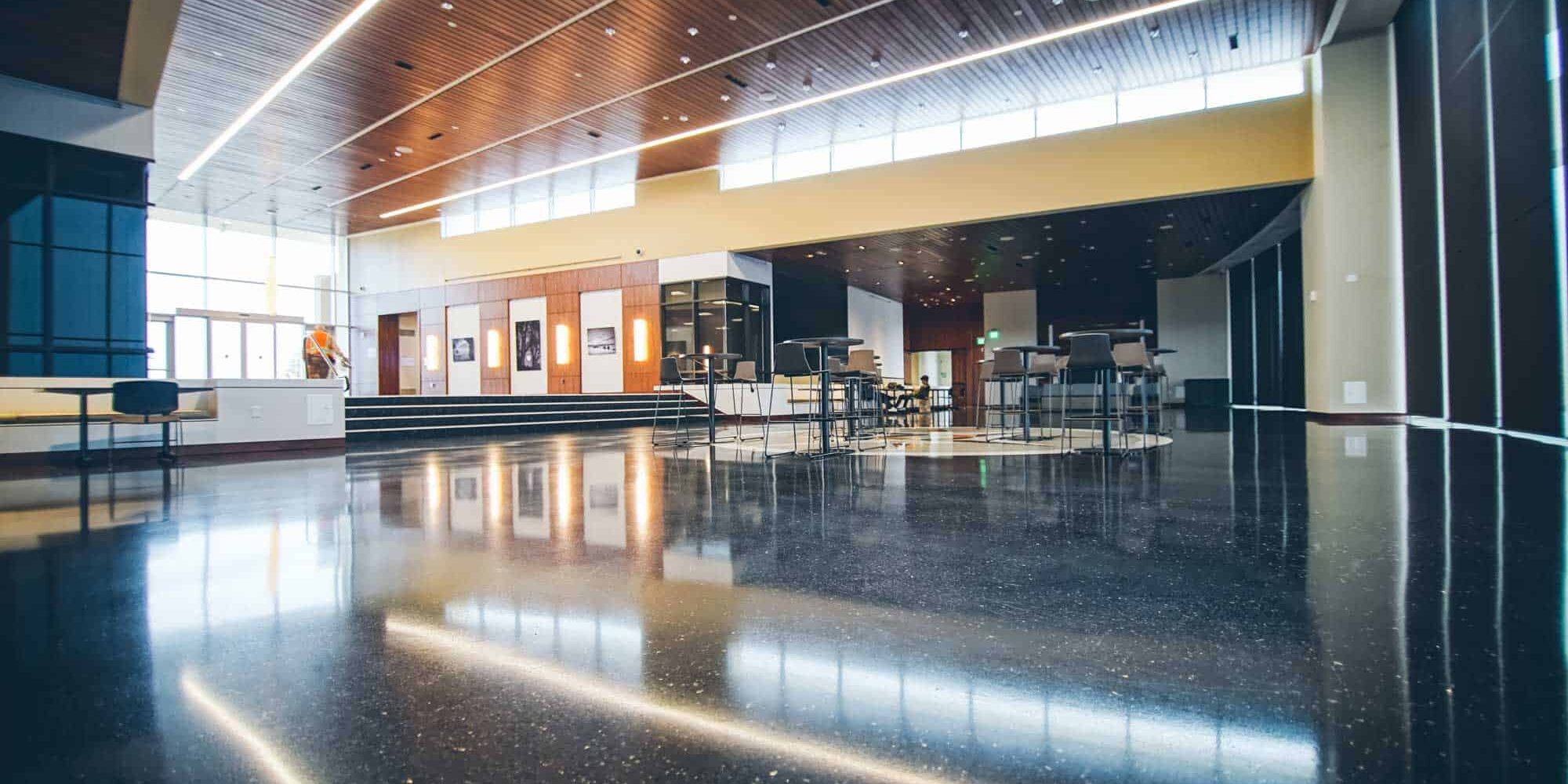

How a new integral color helped a concrete overlay look like terrazzo for $20 a square foot cheaper.

In the San Franciscan suburb of San Bruno, Calif., Skyline College just unveiled the newest addition to its campus – the 21,000-square-foot, multipurpose Environmental Science Building.

Overlooking the Pacific Ocean, this building houses laboratory classrooms, lecture halls, academic offices, a catering kitchen and a gallery that optimizes its dazzling ocean views.

Though the gallery floors aren’t the primary spectacle in this space, they offer their own “wow” factor. That was the intended outcome from the very beginning of this $40.7 million project.

“Usually there’s not a lot of decorative flooring thrown into county and state campuses,” said Bonnie Boden, senior project manager with flooring contractor Floor Seal Technology. “However, this project is very exclusive, very different, very private. It looks over the Pacific Ocean, it sits on the back side of the college, and their intent is to sell it as a luxury, exclusive event center. We are in the Bay Area. We have a lot of high-tech companies and private events that will utilize this space.”

For a floor befitting this use, terrazzo was originally proposed, as per the vision of Ron Galatolo, chancellor of Skyline College and the San Mateo County Community College District to which it belongs.

“Originally this was supposed to be terrazzo, but Ron didn’t like the way that terrazzo tends to be wavy, and if it does scratch, it turns white,” Boden said. “He had the idea of a black overlay colored concrete floor.”

His idea led Boden’s team to a new product from PROSOCO called Integral Color for Overlays, a liquid concentrated pigment that colors cement mixtures in overlay applications on concrete floors.

There was more than one advantage to the flooring option of a polished concrete overlay, a self-leveling floor topping experiencing a recent surge in popularity.

As it turned out, the overlay option would deliver Galatolo’s desired aesthetic effect at a lower cost than terrazzo.

“One of the highlights of doing an overlay cementitious floor versus terrazzo is the cost difference,” Boden said. “The cost could be substantially less, if not twice as less than a typical terrazzo floor. When you do add a little more decorative aggregate, the (cost per) square foot does go up a little bit, but you’re still talking about at least $20 a square foot less than the terrazzo.”

Boden’s firm, Floor Seal Technology, was first contacted by the project architect, DES Architects, in 2018, and began work on mock-ups immediately.

“There were about five or six mock-ups that they wanted produced with color variation and aggregate size,” Boden said. “They wanted a very, very black floor. We went through many mock-up scenarios with the shades of black. We probably produced around 18 to 20 different warehouse mock-ups to show, which came to the result of what we have here today. We are using PROSOCO Consolideck Integral Color for Overlays, along with five to six different variations of black and colored glass aggregate.”

Perfecting the overlay process with mock-ups prior to installation is critical, according to Matt Herz, PROSOCO’s Technical Specialist for concrete flooring projects in California.

“The architect wanted to get the darkest floor possible,” Herz said. “In order to do that, PROSOCO was involved with at least four mock-ups on site here with different types and concentrations of aggregate as well as different concentrations of color.”

He also accounted for what would be done to the floor after the overlay was poured.

“With an overlay like this, it can pour out and look really dark, but once you get a grinder on there to start going through the honing phases, it can lighten up a little bit,” Herz said. “So that’s why it’s very important to make sure that the color is correct. And you have to do a series of mockups to get that done.”

“One of the highlights of doing an overlay cementitious floor versus terrazzo is the cost difference. The cost could be substantially less, if not twice as less than a typical terrazzo floor.”

Bonnie Boden

Senior Project Manager for Floor Seal Technology

One characteristic of PROSOCO’s Integral Color for Overlays that helps with color consistency is that it’s a liquid, making it easier to achieve uniformity of color in the mixture.

“When you’re talking about a liquid versus a powder, the liquid is already pre-diffused, so when you put the pigment in, it’s going to blend a lot more thoroughly into the mix than a powder would,” he said. “If you’re running a powder type of a pigment, it will clump up in the floor. In this case, this is black so you might have areas that look more gray and other areas that are a lot darker. You’ll have a blotchy floor, and you’ll be able to see where the pigment wasn’t mixed properly.”

The mock-up period ended once the team determined the ratio of cement mixture to liquid colorant for the desired color and aesthetic of this floor.

“Typically, we’re going to mix one 10-ounce bottle (of Integral Color for Overlays) per 50-pound bag of material,” Herz said. “You can have a higher concentration of color in the mix like on this floor.”

In addition to the 5,000-square-foot gallery, the overlays would also be used in two corridors and a prefunction area. One pour was executed per section to meet the building owner’s wish for seamless floors in each area.

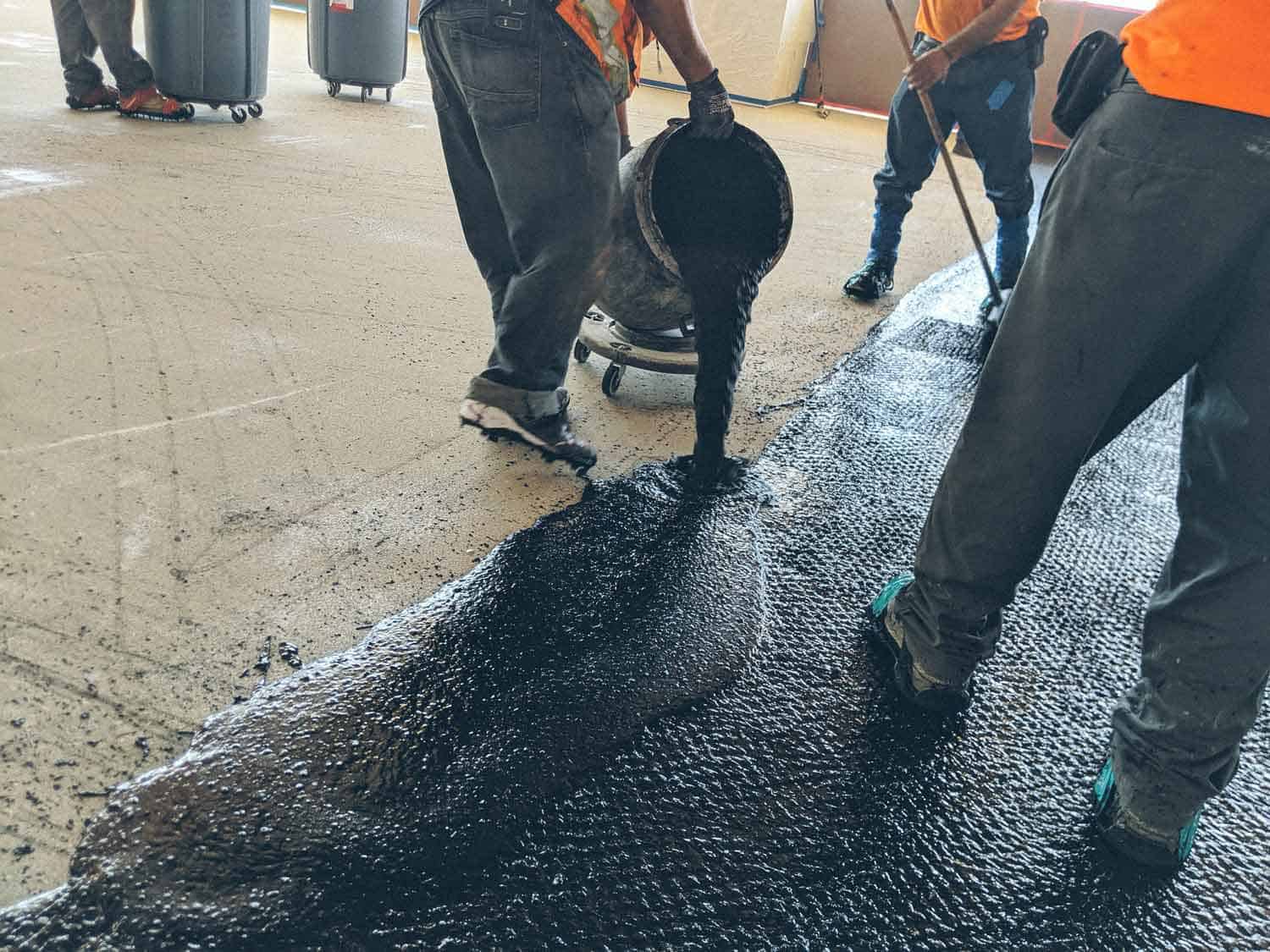

For the gallery, the crew used 315 bags of Rapid Set’s Tru Gray self-leveling cement, mixed with PROSOCO’s new liquid Integral Color for Overlays in black.

The cement, water and color were mixed on-site in a Hippo mixer. Half of the aggregate was added into the mixture, and the other half was broadcast over the top of the overlay after it was poured out.

Boden said it took a crew of 14 installers between 8 and 9 hours to complete a 3/8-inch pour, including the aggregate distribution.

The crew then polished the floor with an application of Consolideck LS densifier. Finally, a protective treatment called LSGuard was applied to the floors before a final burnishing step to make the overlay pop.

Overlays are a new type of concrete floor application that she said the installers truly seemed to enjoy.

“These floors are so fun and so creative, and it really takes the installers out of their typical day of doing underlays and moisture sealers and other types of typical standard polishes,” she said. “It really puts them into an environment that’s so highly creative.”

Overlay projects are growing in numbers, and Boden is seeing the growth too. Maybe that’s because the advantages of a concrete overlay are heightened in her region.

“We are in the high-tech industry here,” she said. “We’ve got headquarters of Intuit, Dropbox, Uber, Facebook, Microsoft. A lot of these companies like to control what their floor is going to look like versus just doing a standard concrete with color. They want to be able to color it the way they want to and achieve different types of aggregate exposure. It is a definite advantage to be able to use an overlay to hide all the imperfections standard concrete could have. There’s a lot of turnover in buildings, so utilizing the overlay is very useful to these companies. We’ve got about eight to nine different projects around the Bay Area that are using them.”

It’s likely that Boden’s company will be working with PROSOCO’s Integral Color for Overlays for these future projects. She was impressed with both the product and the on-site project support.

Other integral color products were tested at the beginning of the project, but “PROSOCO was superior in the actual color of the black hue,” Boden said.

“When it came to the on-site logistical management, PROSOCO was there, prior to all of the pours making sure the color was shipped to us in a manner that was manageable to pour all of that color into the mixes. And then they stayed with us throughout the entire process of the pour, trying to support us in any possible way with this different application.”

The team approach is particularly satisfying when the job is done and you’ve got something beautiful to show for your work.

“They really enjoyed piecing this whole thing together,” Boden said. “This has been about a year and a half in the making. Finally making something that looks really great and successful, when it all just comes together is pretty awesome.”

![]()

More about this product:

Integral Color for Overlays, the latest addition to PROSOCO’s Consolideck line of concrete flooring products, is a pre-measured, concentrated liquid designed to integrally color cement mixtures for overlays and polishable overlays. Available in nine colors, the concentrated colorants blend easily into overlay mixes to produce uniform and consistent color results. Non-hazardous, low-odor, VOC-compliant and water-based, Integral Color for Overlays are readily stocked and available to ship any time. It can be used for overlays in outdoor or indoor applications, and is compatible with other Consolideck products including densifiers, dyes, dustproofers, guards and cleaners.

![]()