How Pressure Washing Systems found its niche by doing things the right way

When Pressure Washing Systems was first established in Chicago in 1989, they were in the business of cleaning… just about anything.

“As a small business without a lot of business experience, we would clean whatever,” says Bill Mologousis, president. “Your dog, your dishes, your curtains. Whatever you needed. Very early on, we had the realization that we couldn’t be everything to everybody.”

Since then, they’ve narrowed their scope of services to three areas of work (building cleaning; environmental cleaning; and disaster and emergency response cleaning) and gotten famously good at those three things.

But it didn’t happen overnight. It took a lot of introspection and discipline to define their core values and then enforce them – that included saying no to jobs that fell outside of their mission, doing things the right way at their own expense, putting integrity above all else, and giving thoughtful, honest answers to three questions.

“We had to figure out three things,” Mologousis says. “What do we love doing? What can we charge enough money for to make a modest profit? And what does the customer perceive as a value-add?”

"Even on a little job, we'll ask (Jim and Jeff Lucas), 'What should we do?' And they'll say, 'We'll meet you there.' When you have that kind of support, the price of admission is cheap."

The windy city

In all cities, Chicago included, there are ample examples of businesses cutting corners to save a buck. Maybe that’s why there was so much room above board, ready for someone like Mologousis to enter the space of doing things the right way and distinguishing himself immediately.

There’s no better illustration of that than PWS’s foray into rinsewater containment.

“In the early 1990s, we realized there’s a huge gap in wastewater from building cleaning projects and that was impacting the environment,” he says. “We really dug in deep and created PWS Environmental. We made major strides. We really pioneered the water reclamation, water capturing and disposing process.”

That’s no hyperbole. Today, PWS owns a fleet of 40 trucks that are completely self-contained, meaning they can wash a building, pick up the wastewater, treat it on the truck with a sophisticated filtration system, and reuse that water to keep washing the building, with zero impact to the environment and ability to reuse water.

“It’s a closed-loop system, so we really never discharge anything into the environment,” Mologousis says. “We patented all the technology, including the closed-loop system. Seventy percent of our fleet is capable of doing closed-loop cleaning. It’s expensive but it’ll get better as technology catches up. This will ultimately be the way people clean things in the future.”

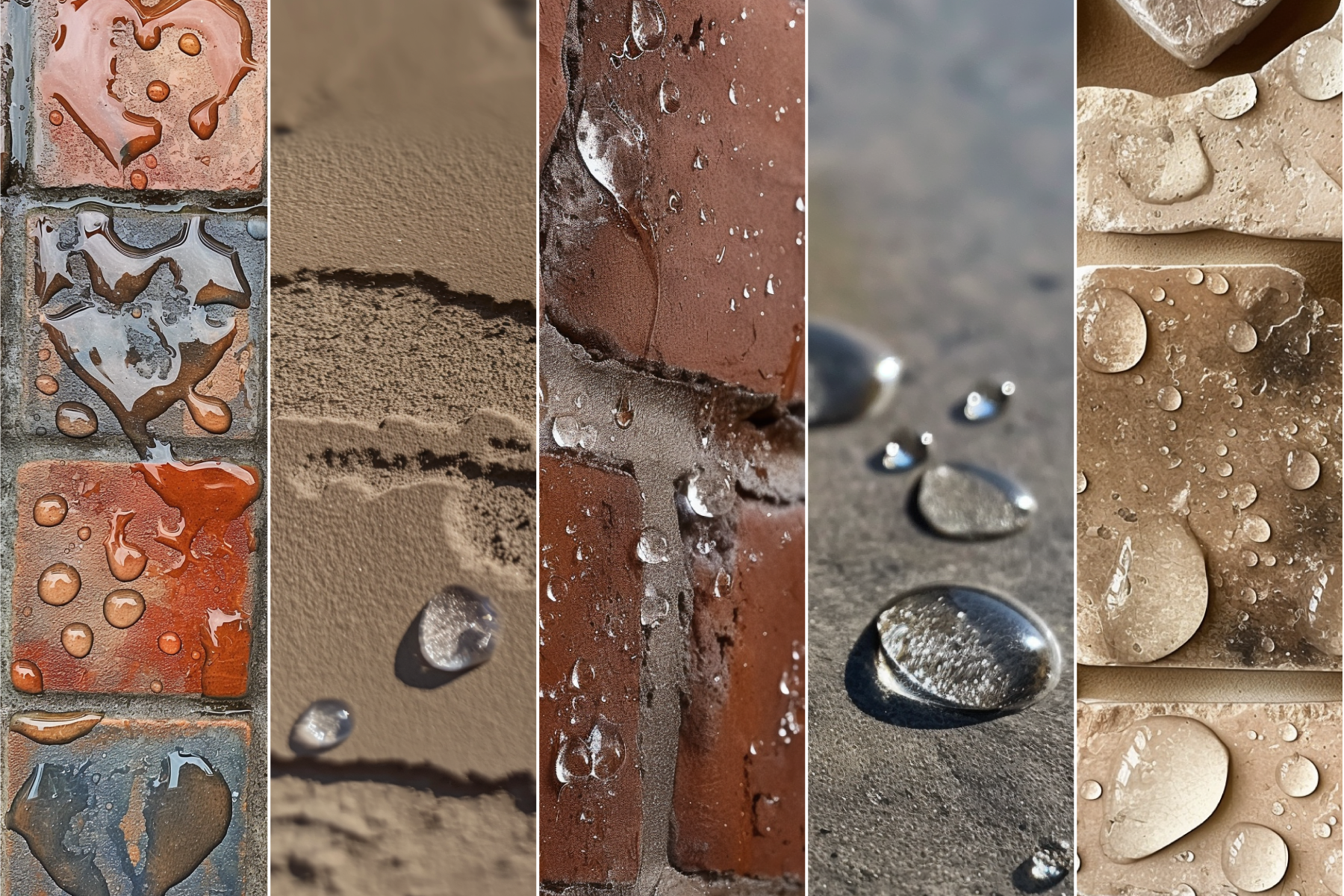

Because of their focus on environmental cleaning, one of their top cleaners is PROSOCO’s Enviro Klean 2010.

“We use 2010 more than anything else because it’s so environmentally friendly and it does a great job on most masonry, especially brick masonry,” Mologousis says. “On projects where 2010 is not going to do it, we’ll use 766 Limestone & Masonry Prewash, and Limestone & Masonry Afterwash. We also do a lot of sealing work, and you guys have a bunch of great sealers. We use a lot of SafRestorer. And for deep staining, we’ll use your poultice cleaners.”

"A big part of what we do is educating the consumer and making sure they have all the information to make the right decisions to clean the building. ”

The company’s focus on disaster and emergency response cleanings enabled its growth of this division to a national scale. As just one example, PWS was on-site after Hurricane Ian to clean 3 million square feet of the second-largest distribution center in the country from the inside out.

“The distribution center had failed during the storm,” Mologousis says. “We cleaned it with 2010. We use PROSOCO products a lot. We love your products. They’re effective, consistent, safe and fire-friendly. A big piece of our business is environmental cleaning and not letting what we do impact the environment in a negative way. We believe in being good stewards of our environment.”

Unfortunately, not all contractors feel the same way, and Mologousis sees evidence of that every day.

“I think people have been a little bit lax after Covid and the downturn in 2008 and 2009,” Mologousis says. “People got away from doing things the right way. It’s disappointing. The West Coast is still pretty stringent. But we see the worst of the worst in even the most sophisticated municipalities and universities that have no understanding that it’s even an infraction.”

That means for PWS, a lot of time is spent simply educating clients on best (and legal) practices.

“A big part of what we do is educating the consumer and making sure they have all the information to make the right decisions to clean the building. Most clients don’t want us to represent them in a way that’s less than they would represent themselves. We’re not coming into the conversation trying to scare people or tell them what they have to do, but just educating. We’re not an enforcement agency, we’re a vendor, and we can’t force people to do things that don’t want to do things right.”

According to Mike Millette, senior estimator at PWS, it may be just a matter of time before things change even for the worst offenders.

“They may not be able to get away with it in the future for much longer,” he says. “The larger you are, the more people are over your shoulder. For many years, the large companies have liked being able to press the easy button.”

"We use 2010 more than anything else because it’s so environmentally friendly and it does a great job on most masonry, especially brick masonry. ”

The right reps

PWS credits a lot of their success to the cache and reputation of two of the most experienced masonry cleaning professionals in all of Chicago – Jim and Jeff Lucas.

"We don't use anything else but PROSOCO and I'll tell you why,” says Mologousis. “One, it's proven. Two, it works. Three, we've got the support of the Lucas brothers and PROSOCO. When something goes wrong, at least when there's a perceived problem on a project, they come in, they give you the expert opinion, they don't bend the rules, and their integrity is off the charts.”

When Millette first met Jeff Lucas, he was somewhat new to the industry but immediately got the sense that Jeff was a good person to have in his corner.

“We were meeting at a job site, and Jeff took one look at the job and said, ‘This is Indiana limestone and it was quarried between 1895 and 1909.’ I thought, ‘This is the right guy.’”

Mologousis remembers a particular project where Jeff’s presence made a world of difference.

PWS had performed spot-cleanings on both buildings that make up Chicago’s Federal Reserve – one was built in the 1920s and one was built in the 1980s. In 2021, PWS again won a contract to clean the entire complex.

“It was a full-on restoration,” Mologousis recalls. “Every window had to masked, every one of seven or eight different substrates and materials had to be treated differently. The 1980s building hadn’t been cleaned and was showing signs of natural erosion from water rundown that when you looked at it from a distance, it looked like streaking. The architect said, ‘I don’t like it, I need it clean.’ It didn’t get any better (after another application), and we were pretty confident that it was as clean as it would get. The architect said it still wasn’t good enough. He really dug in his heels. I called Jeff Lucas and said, ‘Jeff, I need you to meet me at this building and meet this architect,’ because when Jim or Jeff write a letter, it’s over. Jeff and I were walking across the street about a quarter of a block away, where we meet the architect. The architect knew Jeff, who said ‘Listen, I already looked at the building. It’s perfect, it’s just erosion and it’s not going to get any cleaner.’ We never even looked at the building. Jeff had enough street cred. Then we went to dinner.”

Jeff Lucas remembers that project well and lobbies the praise back at PWS.

“I have a lot of respect for Bill and Mike and their whole organization,” Lucas says. “Bill is very passionate about the company, Mike is always following up with customers, and Tony knows cleaning inside and out. Their division that handles reclamation is very well set-up. PWS has the ability to handle big jobs, and they have found a very good niche.”

Lucas added that the two businesses have helped one another grow in tandem over the years. It’s a great match considering they share a mission of unyielding integrity.

“Jeff and Jim are just premium guys,” Mologousis says. “They never tell us they can't come out. Even on a little job, we'll ask them, 'What should we do?' And they'll say, 'We'll meet you there.' When you have that kind of support, the price of admission is cheap."

![]()