RILEM tube tests are used to evaluate the performance of water repellents in the field. There are two types of RILEM tubes, 5.0 mL (tall) tubes and 60 mph (short) tubes. Procedures for the 5.0 mL tube and 60 mph tube are described below.

Tech Note 102

Compiled September 1987

Revised July 2020

Author(s)

PROSOCO

Location

3741 Greenway Circle

Lawrence, KS 66046

Contact

prosoco.com

800-255-4255

customercare@prosoco.com

Introduction

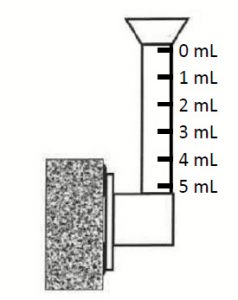

RILEM tube tests are used to evaluate the performance of water repellents in the field. There are two types of RILEM tubes, 5.0 mL (tall) tubes and 60 mph (short) tubes. The 5.0 mL tubes are use on brick, natural stone, cast-in-place concrete and precast concrete. The 60 mph tubes are used on concrete masonry units. Putty is used to affix the tube to the vertical or horizontal surface and water uptake is measured during a 20-minute time period. Procedures for the 5.0 mL tube and 60 mph tube are described below.

RILEM Tube Procedure for Brick, Natural Stone, Cast-in-place, and Precast Concrete

The 5.0 mL RILEM tube has been the mainstay of field-testing procedures for many manufacturers of water-repellent products. It allows for the only practical, rapid, nondestructive evaluation of comparative water-repellency in the field. Properly conducted, the test procedure allows for a quantitative evaluation of water repellency of both the masonry unit and the unit/mortar interfaces.

Procedure:

Procedure:

1. The masonry surface should be clean, dry, and free from poorly adhered coatings and/or partially spalled masonry fragments.

2. Roll out a bead of the putty to approximately ¼” diameter and 6” length. Attach the putty to the flat brim of the tube.

3. Firmly press the tube with the attached putty to the surface. Press in any putty that extrudes to form a tight seal.

4. Fill the tube with water to the appropriate level, ensuring no air is trapped inside the body. If air is trapped inside or the putty leaks, remove the tube and repeat the procedure in a new area.

5. Wait for 20 minutes and then record the amount of water absorbed by the substrate.

Where warranty considerations exist, the following criteria will be applied when determining whether the performance will qualify for an extended warranty:

| Max. wind-driven rain at 20 minutes | 10 Year (Material & Labor) | 10 Year (Material Only) | 5 Year (Material & Labor) | 5 Year (Material Only) |

|---|---|---|---|---|

| 1 mL or less loss | Yes | Yes | Yes | Yes |

| Greater than 1 mL loss | No | No | No | No |

Download this Tech Note as a PDF

RILEM Tube Procedure For Concrete Masonry Units

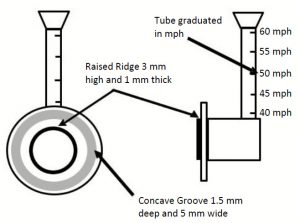

It has become increasingly apparent that concrete masonry units present some unique challenges with respect to water intrusion. The high porosities and the large capillaries in these units render many traditional water-repellent technologies ineffective. Not only has water-repellent technology evolved to address these challenges, but also field-testing procedures have now been revised to incorporate techniques suitable for these materials.

Procedure:

Procedure:

1. The masonry surface should be clean, dry, and free from poorly adhered coatings and/or partially spalled masonry fragments.

2. Roll out a bead of the putty to approximately ½” diameter and 6” length.

3. Place the putty in the concave groove on the flat brim of the tube.

4. Firmly press the tube with the attached putty to the surface. Press in any putty that extrudes to form a tight seal.

NOTE: The presence of the raised ridge on the underside of the flange makes this step especially important. Compression of the putty will not be as great as with the traditional assembly and therefore a complete seal may not be achieved if this step is omitted.

5. Evaluate the assembly to ensure the putty has not extruded into the “bowl” area of the tube and is not interfering with the test area.

6. Fill the tube with water to the 60 mph level, making sure no air is trapped inside the body. If air is trapped inside or the putty leaks, remove the tube and repeat the procedure in a new area.

7. Wait for 20 minutes and then record the maximum wind-driven rain speed that the treated concrete masonry units can withstand.

Where warranty considerations exist, the following criteria will be applied when determining whether the performance will qualify for an extended warranty:

| Max. wind-driven rain at 20 minutes | 10 Year (Material Only) | 5 Year (Material & Labor) | 5 Year (Material Only) |

|---|---|---|---|

| 60 mph | Yes | Yes | Yes |

| 55 mph | No | Yes | Yes |

| 50 mph | No | No | Yes |

| <50 mph | No | No | No |

* Final results can be the average of all tubes on each elevation or from the majority of tubes used. We recommend at least 5 tubes per elevation and testing sites should include head joints, bed joints and the Custom Masonry Unit itself.