Commission 25-PEM is a technical committee within RILEM (Reunion Internationale des Laboratoires D'essais et de Recherches sur les Constructions) that has developed tests to measure the deterioration of stone and to assess the effectiveness of treatment methods.

Tech Note 103

Compiled September 1987

Revised July 2020

Author(s)

Frances Gale

PROSOCO

Location

3741 Greenway Circle

Lawrence, KS 66046

Contact

prosoco.com

800-255-4255

customercare@prosoco.com

Introduction

RILEM (Reunion Internationale des Laboratoires D'essais et de Recherches sur les Materiaux et les Constructions), with headquarters in Paris, is the International Union of Testing and Research Laboratories for Materials and Structures. As with our American Society for Testing and Materials (ASTM), Technical Committees are formed within RILEM to develop standard methods for measuring properties and evaluating the performance and durability of many different building materials.

One such technical committee, Commission 25-PEM, has developed tests to measure the deterioration of stone and to assess the effectiveness of treatment methods. The standard tests drafted by Commission 25-PEM fall within several categories, including methods for detecting the presence and movement of water (II.), for determining internal cohesion (III.), and for measuring mechanical surface properties (IV.). Within category II., is Test Method No. II.4, designed to measure the quantity of water absorbed by the surface of a masonry material over a definite period of time.

RILEM Test Method II.4 provides a simple means for measuring the rate at which water moves through porous materials such as masonry. The test can be performed on-site or in the laboratory and can be used to measure vertical or horizontal water transport. Water permeability measurements obtained in the laboratory can be used to characterize unweathered, untreated masonry. Measurements made on-site (or on samples removed for laboratory testing) can be used to assess the degree of weathering that the material has undergone. Test Method II.4 can also be used to determine the degree of protection afforded by a water-repellent treatment. The theoretical basis on which the method is based, the equipment and procedure for conducting this test, and the several applications of the test data are all provided and discussed in paragraphs below.

Download this Tech Note as a PDF

Theory

Because masonry building materials are porous, they are all partially permeable to water. The interior structure of a masonry material is a system of fine interconnected pores. Wetting of a surface involves capillary conduction (suction) through this pore system, proceeding along both vertical and horizontal pathways. Vertical transport occurs when ground water enters at the base of a structure or as rainwater through leaking gutters. Horizontal transport occurs when driving rain penetrates into wall surfaces. (Under actual conditions, the amount of rain penetration depends on prevailing wind conditions as well as on the composition and condition of the exposed surface.)

When water comes into contact with a masonry surface, wetting proceeds through the material as a front. Accurate measurements of the advance of this wetting front made on a variety of masonry building materials have demonstrated that the characteristic wetting rate and pattern of each material are directly related to its capillary structure and port size distribution. In fact, rate constants have been measured for brick, limestones and other masonry materials. RILEM Test Method II.4 provides a simple method for measuring the volume of water absorbed by a material within a specified time period.

Equipment

The equipment necessary for measuring water absorption under low pressure is simple. The test can be performed on-site or in the laboratory with a test apparatus available in two forms. One is designed for application to vertical surfaces and measures horizontal transport of water, or, its resistance to wind-driven rain penetration.* A second form is designed for application to horizontal surfaces and measures vertical transport.

The equipment necessary for measuring water absorption under low pressure is simple. The test can be performed on-site or in the laboratory with a test apparatus available in two forms. One is designed for application to vertical surfaces and measures horizontal transport of water, or, its resistance to wind-driven rain penetration.* A second form is designed for application to horizontal surfaces and measures vertical transport.

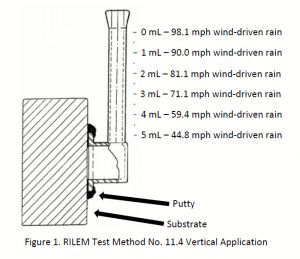

Figure 1 illustrates the pipe-like apparatus designed for vertical surfaces. Its flat, circular brim (at the bottom end of the pipe) is affixed to the masonry surface by interposing a piece of putty. The open, bottom end of the pipe has an area of 4.9 cm2. The vertical tube is graduated from 0 to 5 mL with each gradation representing an increment of 0.5 mL (it is therefore possible to estimate to 0.25 mL). The total height of the column of water applied to the surface, measured from the center point of the flat, circular brim to the topmost gradation, is 12 cm. This corresponds to a pressure of 1177.2 pascals (approximately 0.17 psi), or, a dynamic wind pressure of 157.8 kilometers per hour (approximately 98.1 mph).

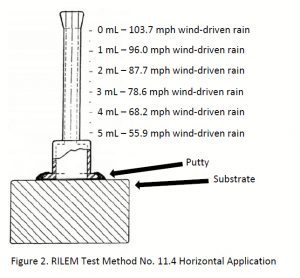

The apparatus designed for application to horizontal surfaces, similar to the one for vertical surfaces described above, is illustrated in Figure 2. The horizontal tube is graduated in the same way as the vertical tube. The total height of the column of water applied to the surface, measured from the flat, circular brim to the topmost gradation, is 13.4 cm. This corresponds to a pressure of 1314.5 pascals (approximately 0.19 psi), or, a dynamic wind pressure of 166.8 kilometers per hour (approximately 103.7 mph).

The apparatus designed for application to horizontal surfaces, similar to the one for vertical surfaces described above, is illustrated in Figure 2. The horizontal tube is graduated in the same way as the vertical tube. The total height of the column of water applied to the surface, measured from the flat, circular brim to the topmost gradation, is 13.4 cm. This corresponds to a pressure of 1314.5 pascals (approximately 0.19 psi), or, a dynamic wind pressure of 166.8 kilometers per hour (approximately 103.7 mph).

*It should be noted that a standard method for measuring water penetration and leakage through masonry is described in ASTM E 514. The ASTM test method is intended to evaluate wall design and workmanship as well as the degree of weathering and the performance of water repellent treatment. It is therefore necessary to conduct the procedure on a test wall built with a minimum height or length of four feet. The wall is exposed to water (3.4 gallons per square feet per hour) in a test chamber for four hours.

Use On Concrete Masonry Units

It has become increasingly apparent that concrete masonry units present some unique challenges with respect to water intrusion. The high porosities and the large capillaries in these units render many traditional water-repellent technologies ineffective. Not only has water-repellent technology evolved to address these challenges, but also field- testing procedures have now been revised to incorporate techniques suitable for these materials.

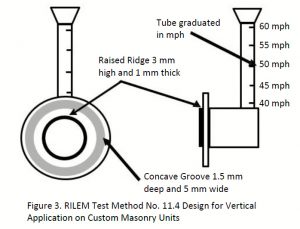

After extensive laboratory testing, PROSOCO redesigned the traditional tube assembly to generate more reproducible results and to minimize the influence of the operator on the test results. The redesign (Figure 3) is easier to use and is available in a unit specifically for testing concrete masonry units.

Highlights of the tube for concrete masonry units:

1. A wider flange for easier sealing to rough surfaces.

2. A guide groove on the flange to aid in placement of the putty.

3. A raised ridge on the underside to prevent putty “filling in” the opening and reducing the area under test.

4. Graduations in miles per hour wind driven rain.

5. A less severe range of wind driven rain simulations that accurately reflect “normal” weather conditions.

The Custom Masonry Unit tube produces a maximum test condition of a simulated 60 mph wind-driven rain. These conditions are typical of those experienced by structures during strong thunderstorms in many parts of the United States and fall slightly short of hurricane conditions which begin at 74 mph.

Procedure

The testing apparatus is affixed by interposing a strip of putty between the flat, circular brim of the pipe and the surface of the masonry material. To ensure adhesion, manual pressure is exerted on the cylinder. Water is then added through the upper, open end of the pipe until the column reaches the "0" gradation mark or the “60 mph” gradation mark (depending on the RILEM test method). The quantity of water absorbed by the material during a specified period of time is read directly from the graduated tube. The periods of time appropriate for the test depend on the porosity of the material on which the measurement is being made; generally 5, 10, 15, 20, 30 and 60 minute intervals provide the most useful data. In many cases, it may be important to measure water absorption through the mortar joint as well as the surface of the substrate.

Applications

Water has long been associated with deterioration processes affecting masonry materials. Its presence within the interior pore structure of masonry can result in physical destruction if the material undergoes wet/dry or freeze/thaw cycling. The latter is particularly damaging if the masonry material has a high clay mineral content.

Perhaps of greater importance is the fact that the presence of moisture is a necessary precondition for most deterioration processes. Pollutant gasses are harmful when they are dissolved in water; efflorescence is dependent on the migration of salts dissolved in water; moisture is a requirement for the growth of biological organisms. Because of these factors, the water permeability of a masonry material is related to its durability. Thus, results obtained using Test Method II.4 can be used to predict potential vulnerability of untreated, unweathered masonry materials to water-related deterioration.

Test Method II.4 also provides useful information when carried out on weathered masonry surfaces. Water permeability of a material is affected when its surface is obscured by the presence of atmospheric soiling or biological growth, or when there are hygroscopic salts within the interior. The formation of a weathering crust due to mineralogical changes occurring on the exposed (weathered) surface may substantially affect water permeability measurements. By comparing data obtained on masonry that has been exposed to the elements with measurements made on unweathered samples, it is possible to measure the degree of weathering that has occurred.

Finally, RILEM Test Method II.4 can be used to evaluate the performance of a water repellent treatment. An effective treatment should substantially reduce permeability of the masonry material to water. By doing so, the treatment will reduce the material's vulnerability to water-related deterioration. A comparison of test results obtained on treated masonry samples with those obtained on untreated samples provides information about the degree of protection that can be provided by the water repellent treatment.

References

Amoroso, G. and Fassina, V. Stone Decay and Conservation. Amsterdam: Elsevier Science Publishers, 1983. (See especially Chapter 1, "Effects of water and soluble salts on stone decay".)

Hochman, Harry. "Measuring water permeability of masonry walls" (Technical Note N-1179). National Civil Engineering Laboratory, August 1971.

Sereda, P. J. and Feldman, R. H. "Wetting and Drying of Porous Materials" (Canadian Building Digest 130). Ottawa: National research Council of Canada, 1975.

Stambolov, T. and van Asperen de Boer, J.R.J. The Deterioration and Conservation of Porous Building Materials and Monuments. Rome: ICCROM, 1976.

Torraca, Giorgio. Porous Building Materials. Rome: ICCROM, 1981.