Concrete is the backbone of modern construction. Yet cement production alone accounts for about 8% of global CO₂ emissions. In response to the carbon emissions of concrete production, low-carbon concrete has emerged as an alternative to concrete made with traditional cements like Type 1/2, also known as ASTM C-150. The intention? To cut emissions while still delivering the strength and durability these projects demand, whether they are driveways of new residential developments, or DOT and infrastructure projects. Whether these new cement types (categorically known as ASTM C-595 Blended Hydraulic Cements, one of which is Type 1L cement, also called Portland limestone cement or Portland 1L cement) have delivered on the strength and durability claims, is up for contention.

What Is Low-Carbon Concrete?

At its core, low-carbon concrete is a mix engineered to minimize the emissions associated with cement, the binding component that drives most of concrete’s embodied carbon. This reduction comes from adding raw, or uncooked, limestone to the mix, blending in supplementary cementitious materials (SCMs), utilizing recycled inputs, and optimizing mix proportions. Emerging low-carbon cement technology also contributes to this outcome.

Professionals evaluating what is low-carbon concrete should think in terms of both material inputs and performance outputs: a concrete that requires less clinker, incorporates substitutes like fly ash or slag, and achieves the same compressive strength benchmarks under ASTM testing.

Why Cement Drives Carbon Emissions

Cement production releases CO₂ from two sources: the fuel burned to heat kilns and the chemical reaction (calcination) that occurs when limestone is converted into clinker. This dual release is why conventional mixes have such a large footprint.

Reducing carbon here is not meant to sacrifice structural performance. The intent is to use the right mix design and substitutions to keep the paste strong enough to bond aggregates, resist cracking, and handle long-term loading. That balance is what defines low-embodied-carbon concrete.

Low-Carbon Concrete Mix Options

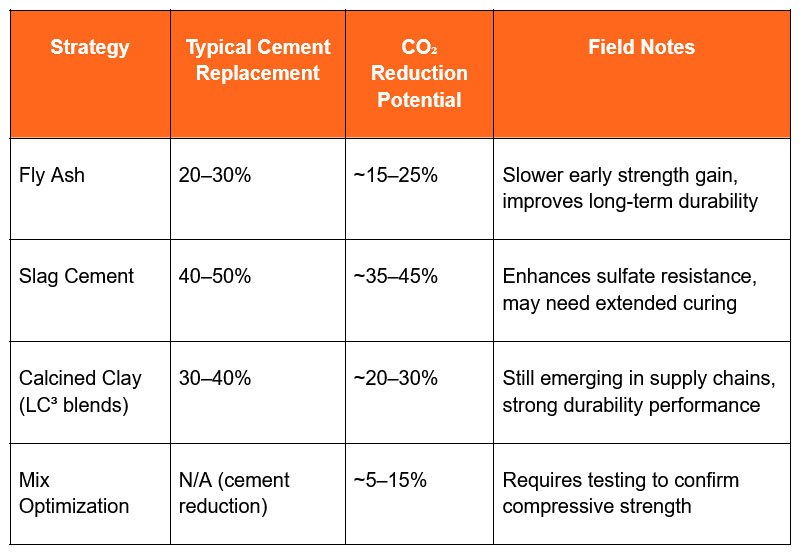

There are several strategies available to reduce the cement load in concrete mixes. Each comes with its own field considerations.

Supplementary Cementitious Materials

Fly ash, slag cement, and calcined clays replace portions of Portland cement while maintaining binding properties. These SCMs react with calcium hydroxide in the mix to form additional cementitious compounds, strengthening the cured product. When specified properly, they cut emissions significantly and can enhance long-term durability. Regional availability matters — not all markets have consistent supplies, and sourcing must be confirmed early in design.

Recycled Aggregates and Fines

Recycled crushed concrete and industrial byproducts can replace a percentage of virgin aggregate. This does not lower binder-related emissions directly but reduces extraction, transport, and landfill impacts. Mixes with recycled aggregate must be tested carefully, as variability in particle strength and absorption can affect consistency and curing. When verified, these substitutions contribute to both material efficiency and reduced project waste.

Mix Design Optimization

This approach prevents overdesign while meeting structural code requirements. Lowering water-to-cement ratios, incorporating admixtures, and calibrating paste content all are strategies designed to reduce unnecessary cement use. With proper testing, it has the potential to produce reduced-carbon concrete that performs as expected in the field.

Benefits of Low-Carbon Concrete

The advantages of adopting low-carbon concrete extend beyond emissions accounting.

First, the environmental impact is measurable. Lower clinker content directly reduces CO₂ release, bringing embodied carbon of projects down to meet stricter benchmarks. Lifecycle assessments consistently show that mixes designed this way carry less total carbon compared to conventional alternatives.

Second, concrete that resists sulfate attack, alkali-silica reaction, and thermal cracking lasts longer, reducing replacement cycles and lowering cumulative carbon over its service life. This durability translates into fewer repairs, fewer material deliveries, and lower long-term environmental costs.

Concrete’s carbon footprint comes mainly from cement content. Even modest substitutions can yield measurable reductions:

- Replacing ~30% of cement with fly ash typically reduces embodied CO₂ by 15–25%, depending on the baseline mix and LCA boundaries.

- Using ~50% slag cement in place of Portland cement often cuts emissions by 35–45% while improving sulfate resistance.

Optimizing mix design to eliminate 50 kg of unnecessary cement per cubic meter saves roughly 40–45 kg of CO₂, based on typical cement emission factors (~0.8–0.9 kg CO₂ per kg cement).

Some research indicates that substituting clinker with LC³ formulations can lower cement-related CO₂ emissions by up to 30%. Together, these strategies demonstrate both project-level reductions and global potential for meaningful impact. Wider industry studies suggest that scaling SCM substitutions across concrete production worldwide could reduce sector emissions by roughly 20–30%.

Finally, the alignment with sustainability frameworks such as LEED and Envision is clear. Projects targeting certification often require Environmental Product Declarations (EPDs) that document embodied carbon reductions. Specifying low-carbon emission concrete is one of the most direct ways to meet those requirements while maintaining strength and compliance.

Standards, Testing, and Compliance

Concrete in sustainable construction still lives under the same performance codes as traditional mixes. ASTM C150 covers Portland cement, while ASTM C618 defines specifications for fly ash, and ASTM C989 for slag cement. These standards guide substitutions while maintaining reliability.

Performance of low-carbon concrete is verified through compressive strength testing, chloride penetration testing, and shrinkage assessments. Compliance is further supported by EPDs that quantify embodied carbon at the mix level. Tools such as OneClick LCA or Athena Impact Estimator allow design teams to measure reductions, compare against baselines, and document results for green building submittals.

The point remains clear: performance depends on conditions. A low-carbon concrete mix that works well in one region with abundant fly ash may not translate directly to another where materials differ. Local sourcing, field trials, and adherence to ASTM standards remain key for reliable results.

Durability and Service Life

As a mid-sized company with an outsized reputation for its industry-leading research and development, PROSOCO has remained first-to-know as its staff members sit on the industry and trade committees making decisions regarding the impact of these new cement technologies. The business has applied its team of chemists to the task of delivering products to densify, protect, clean and decorate concrete made with these dynamic cement mixes. Several PROSOCO products are especially designed to meet the specific characteristics of low-carbon mixes in the real world.

Sealers and hardeners like LS (lithium-silicate) densify concrete to give it abrasion resistance and to reduce dusting. Water repellents limit liquid intrusion while allowing vapor to escape, preventing efflorescence and freeze-thaw damage. Protective coatings block chlorides, sulfates, and other contaminants that drive premature surface breakdown.

By addressing moisture and chemical risks, these treatments maintain structural integrity and extend service life. That ensures the carbon savings embedded in every low-carbon concrete mix are preserved over time. With VOC-compliant formulations, PROSOCO systems also align with the same environmental benchmarks driving adoption of carbon-friendly concrete.

The nature of ASTM C-595 Blended Hydraulic Cements as a building material is ever-evolving, and new designations and formulas are being continuously researched and introduced.

Build Longer-Lasting Structures with PROSOCO Protective Treatments

PROSOCO protective treatments support sustainable construction by extending the service life of concrete specified for reduced-carbon performance. By safeguarding surfaces against moisture, contaminants, and premature breakdown, these products help optimize the performance characteristics of these new cement mixes over time. Contact us today for more information.