We're going to talk about FastFlash in detail. It’s funny to say detail because it is our detailing membrane. FastFlash is the product that's used on all your rough openings, transitions, any kind of penetrations through walls, and transition membranes. When in doubt: use FastFlash. It's a very universal product that could be used in most detailing situations.

Featured in this video

Hit the corners

When you first start a rough opening you want to strike the corners. You run a little bead of FastFlash Gun Grade into the corner, and strike it. The main purpose for this is to create a 45 degree angle instead of 90 degree angle.

Gun it

When preparing your opening with FastFlash, the general rule of thumb is to start at the header. You want to gun your sealant in a serpentine fashion on the header, and then again on the side and the face of the boards.

Spread it

You run the serpentine shape and then you strike it with your Bondo knife. You want to start at the header run down the two jams and then uh hit the sill at the end.

12-15 mil thick

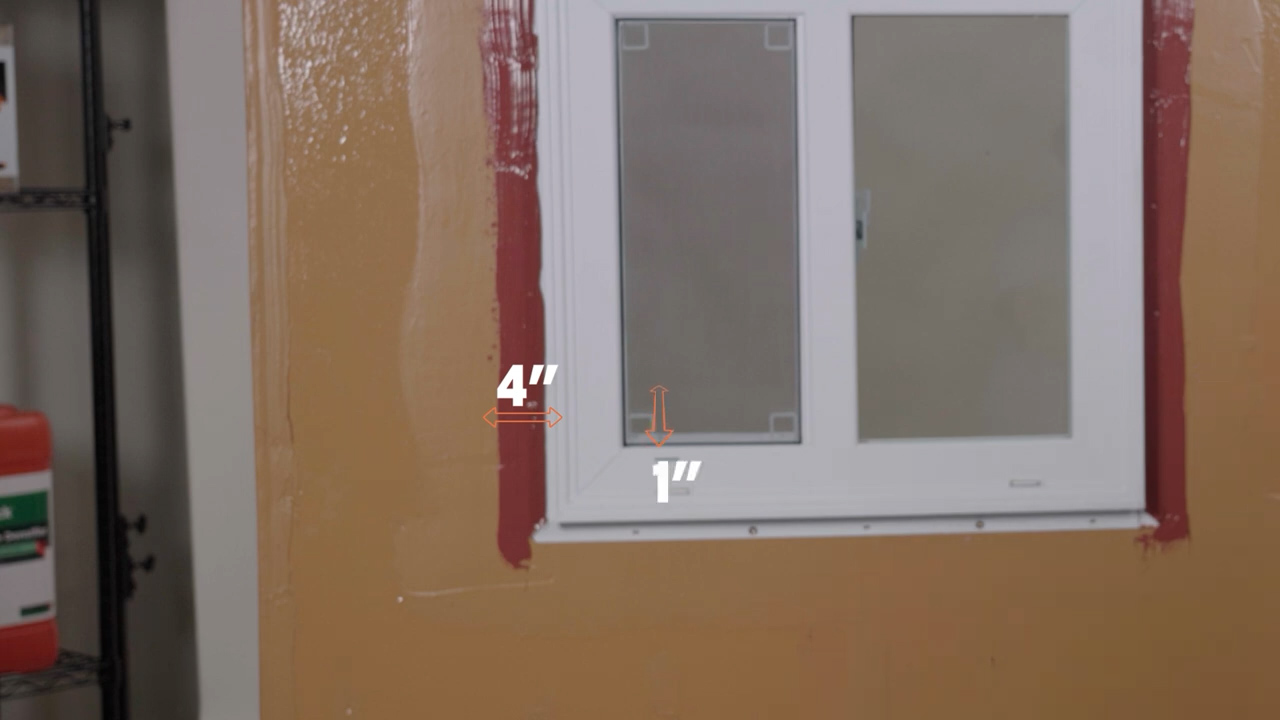

FastFlash is meant to be applied 12 to 15 mil thick. It's a thin mil air barrier system. All of PROSOCO products are thin mil. We require 4 inches on the exterior face of the of a rough opening and then minimum 1 inch past the window on the interior of the rough opening. A lot of specifiers prefer to just say run it the entire way through on the interior of the rough opening which makes it a little simpler to use and less room for error.

FastFlash Roller Grade

In addition to the gun grade FastFlash, we also offer a roller grade FastFlash after you’ve treated corners of your rough opening and any joints and seams that might happen to end in the rough opening with the gun grade, you can come back and roll on the roller grade.

Don't Forget Board Seams & Screw Heads

Nail heads and screw heads need to be treated to keep air and water from leaking into the building envelope. The same is true for any deficiencies, wood knots, or any surface imperfections that may be subject to air/water leakage. You gun a bead of FastFlash gun grade onto the nail or screw head.

Then tool it out with a bondo spreader, caulking tool, or chip brush.

Let it cure

So let's talk cure times. FastFlash uses STP technology which is a moisture cure technology. It likes heat and it likes humidity. The higher the humidity the quicker it'll cure. Most of the time in a high heat, high humidity area you can move on within about a half an hour. It will stay tacky to the touch but as long as it doesn't transfer onto your hand, you're ready to move.

Now that you know how to use Fast Flash and you've completed all of your detail work you're ready to move on to the air barrier.