The polished concrete entryway floor at Tse’bii’nidzisgai Elementary School (pronounced Suh-Bee-Niz-Iz-Guy) features a Navajo wedding basket design. The design is rich with meaning for the initiated.

It’s a marriage of practical and esoteric, written in concrete at a remote Navajo elementary school set among the towering red buttes and mesas of America’s fabled Monument Valley, Utah.

When you stand on the polished concrete of Tse’bii’nidzisgai Elementary School’s main entryway, you stand upon an iconic design central to Navajo life and understanding of the world.

The school’s name is pronounced “Suh-Bee-Niz-Iz-Guy,” says Project Architect Brian Parker, MHTN Architects, Salt Lake City. Parker worked closely with tribal leaders and teachers to first learn, and then incorporate Navajo culture into the school’s design.

“That experience was one of the greatest moments of my career,” he said.

The pattern in the approximately 1,000 square-foot entryway is taken from the traditional Navajo wedding basket design. Its central spot represents Mother Earth and the beginning of the world. The dark rays spreading out show the journey of life through clouds and mountains.

The red band is said to symbolize the sun, or rainbow, according to Utah’s State Historical Society.

The polished concrete floor in the school’s cafeteria/multi-purpose room features a design drawn from classic Navajo blankets. It was suggested by students, Parker said.

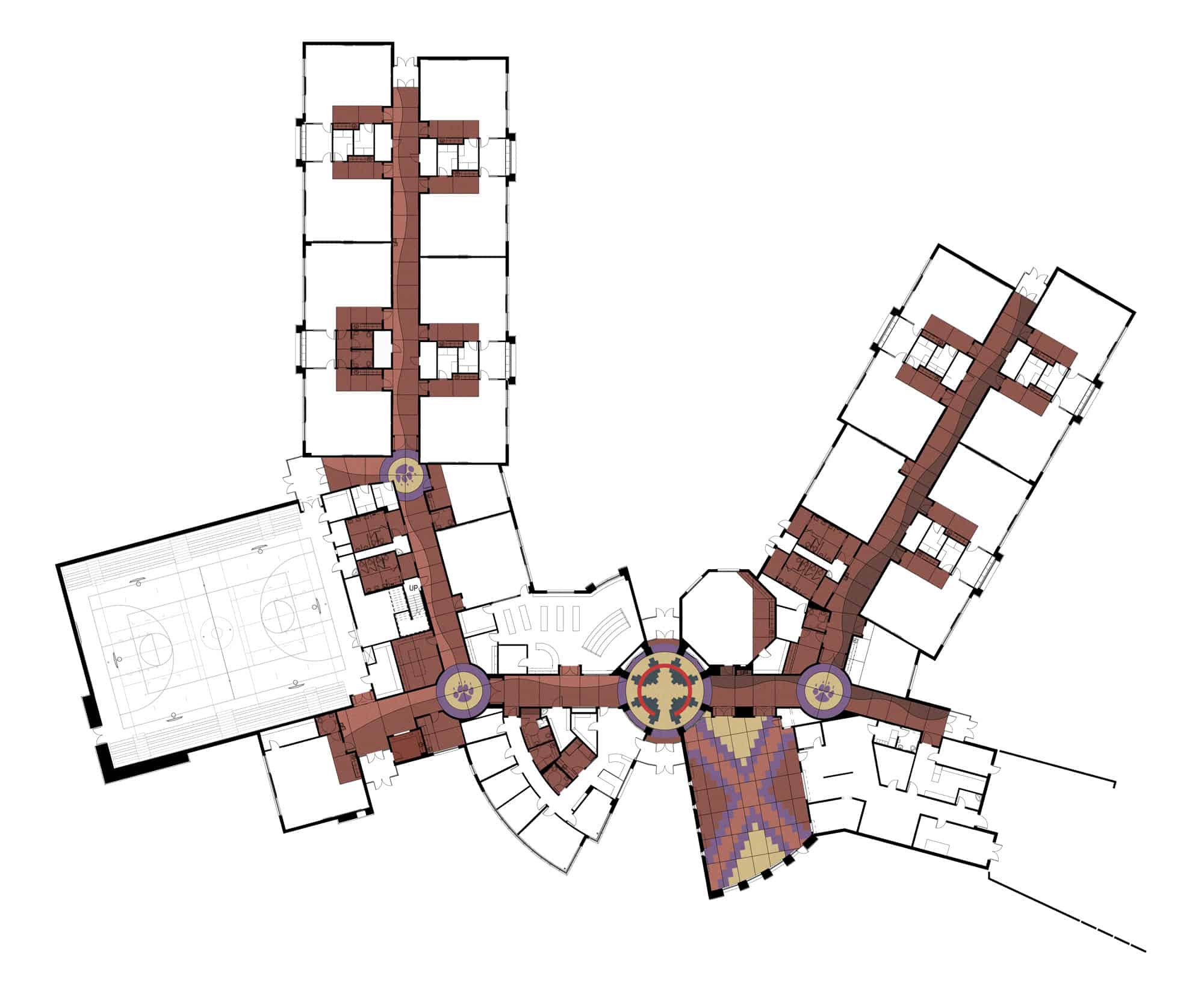

This floor plan for the Tse’bii’nidzisgai Elementary School shows the location and approximate colors of the polished concrete floors throughout the school. Copyright MHTN Architects

The round entryway structure is reminiscent of the traditional Navajo Hogan. Clerestory windows and a generous skylight keep the space alive with natural light, and the polished concrete gleaming.

The client, Utah’s San Juan School District, chose polished concrete as the medium for rendering the design, as well as for the rest of the school.

“They wanted something practical and durable,” Parker said. “Those floors have to stand up to hundreds of kids, year after year.”

Tse’bii’nidzisgai Elementary School is the district’s first experience with concrete floors. “It’s a bit of an experiment,” Parker said. “Though you pay a little extra for polished concrete installation compared to other flooring choices like VCT, if you do it right, you save money on life cycle costs.”

The savings stem from not having to repeatedly scrub, strip, wax or replace worn topping surfaces, Parker explained. He said the district plans to monitor the floors’ performance and cost-savings over the next three years.

Initial reports are good, he said. The floors have already proven to be lower maintenance than other flooring choices.

“The custodians seem to love the floors,” he said.

Work began as Bryan Borcher, Intermountain Concrete Polishing, Meridian, Idaho, brought his 900-pound grinders to flatten and prep the floor for polishing. The massive machines took the floors from a steel-troweled finish to the edge of polish with a succession of ever finer-grit pads.

Hogan Construction & Associates, Salt Lake City, the project G.C., used their own smaller machines for the final polishing from a 400-grit finish to a glossy 800-grit, said Project Manager J.D. Forbush.

Along the way, the installers hardened and densified the approximately 52,000 square feet of concrete floor with Consolideck® LS® lithium-silicate hardener/densifier.

After grinding, the LS® prepped the floors for polishing by filling microscopic concrete pores with tough calcium silicate hydrate – the same hard substance that makes concrete hard to begin with. Less porosity means the surface polishes faster and more effectively.

It also means the finished floor has greater stain- and abrasion-resistance than untreated concrete.

They decorated the polished concrete with water-based Consolideck® GemTone stains, in colors Desert Sand, Georgia Clay and Espresso.

The Hogan Construction crew then applied a micro-thin layer of Consolideck® LSGuard®. The protective treatment, burnished on at 3,000 rpm, liquefies and melds with the concrete for additional stain-resistance and gloss that never needs to be replaced.

LSGuard® contains lithium silicate for a further hardening/densifying effect, which is why it bears the “LS®” prefix.

“We chose Consolideck® products because they’ve worked well on our other projects,” Forbush said. “And they have good field support.”

They needed field support on this project, Forbush said. Though decorating the interior floors went smoothly, the brutal July heat and wind made coloring about 25,000 square feet of exterior concrete recreation area difficult.

Forbush’s crew decorated the exterior concrete with Consolideck® ColorHard. ColorHard is a mix of colorant and LS®. After stirring a packet ColorHard dye into a bucket of LS®, you simply spray and spread the mixture onto the concrete.

You get hardening, densifying and decoration all in one simple step.

The problem was that the bone-dry concrete almost instantly sucked down the mixture’s water component, while heat and wind quickly dried the colored hardener/densifier on the surface, before it could penetrate. Even though the crews applied the ColorHard between 5 and 6 am, before the heated winds really kicked up, they still had trouble with warmth and excessive dryness.

“The local PROSOCO sales manager, Bruce Ferrell, showed us what do,” Forbush said. “He was pretty good.”

Forbush explained that Ferrell had the crew change out LS® for LS/CS® in the ColorHard mix. LS/CS® penetrates more quickly because it’s a thinner formulation, Ferrell told the crew.

He also had them boost the water content of the mix, though he recommended using pure water to do that. Tap water may contain chemicals and minerals that can affect the densifier. Construction-site water is often really bad, Ferrell says, since it’s usually full of rust, minerals, sediment, and other potential contaminants.

With those adjustments made, the ColorHard went down fine, Forbush said.

Application of a water-based water and stain repellent locked the color into the outside concrete against summer monsoon rains, soft-drink spills and other agents of destruction.

On the inside, the one thing you really have to be careful of is protecting the finished floors from other trades during construction, said Colby Davis, the school district’s director of buildings and grounds. He explained that even though the floors are durable concrete, their appearance can be marred by heavy construction traffic and materials.

“In the end it turned out fine,” he said. “We even saved money with the LSGuard®. It made our 800-grit finish look shiny as a 1200-grit finish, without the extra labor cost. It adds some protection, too.”

“People love these floors,” Davis said. “They love the colors, the patterns, the natural looks. These floors bring the natural beauty of our Monument Valley location into the building.”