Every marble surface behaves differently under exposure. Countertops absorb oils and acids, while showers and exteriors draw moisture deep through their pores. The best marble sealer penetrates those capillaries to block liquids from within, forming a breathable barrier that lets vapor escape and keeps stone stable through wet-dry cycles.

What to Look for When Choosing the Best Marble Sealer

Marble’s mineral structure allows moisture to migrate below the surface, carrying stains that dull the finish. A professional-grade sealer forms an invisible network inside those pores rather than a film on top. The goal is always the same: stop liquid absorption while letting internal moisture dissipate.

Silane and siloxane molecules bond with calcium in the marble matrix, converting surface hydroxyls into hydrophobic groups. This reaction doesn’t block vapor, it simply changes the way the surface interacts with water. Sealers don’t make marble waterproof; they give users time to wipe spills before staining occurs.

Penetrating vs Topical Sealers

Two broad categories exist.

- Penetrating (impregnating) sealers soak below the surface and react chemically with the mineral structure, creating durable, vapor-permeable protection.

- Topical sealers form a surface film that can peel or discolor under traffic or UV light. All four formulations use this penetrating chemistry, no plastic film, no trapped moisture, no color change.

Finish and Porosity Considerations

Polished marble resists penetration and usually needs one carefully timed coat, while honed or textured finishes absorb faster and may require two light coats applied wet-on-wet.

VOC and Safety Guidelines

Interior projects, especially countertops and shower stalls, require low-odor, low-VOC sealers. Exterior stone exposed to sun, rain, and freeze-thaw cycles performs better with solvent or hybrid formulas that reach further into the stone. With those factors in mind, the following sealers demonstrate field-tested performance across different marble applications.

PROSOCO Marble Sealers and Their Applications

Each treatment protects marble while preserving its natural finish. The shared property, breathability, prevents moisture buildup beneath the surface while keeping contaminants out.

1. Natural Stone Treatment (Solvent Formula)

A silane/siloxane blend designed for dense, exterior marble and other calcareous stone, Natural Stone Treatment penetrates deeply, bonding within the surface to create long-term water repellency that won’t yellow or peel. Crews often choose it as the best marble sealer for façades, decks, and exterior walkways exposed to UV light or driving rain.

Typical yield: 75-150 square feet per gallon depending on finish. Provides multi-year protection under typical exposure before re-treatment is needed.

2. Natural Stone Treatment VOC

For areas enforcing strict emissions standards, this compliant solvent version delivers equal durability and depth. Natural Stone Treatment VOC is ideal for commercial façades or interior lobbies with limited ventilation. This formulation performs as the best marble sealer for transitional spaces where indoor comfort meets outdoor exposure, reducing water absorption by more than 90% in ASTM C97 testing.

Coverage: 100-175 sq ft per gallon. Delivers long-term repellency under normal exposure conditions.

3. Natural Stone Treatment WB (Water-Based)

When odor limits or indoor air-quality goals rule out solvent use, this water-based formula provides equal protection with easy cleanup. It’s frequently selected as the best marble sealer for countertops, backsplashes, and interior floors. Slight water beading confirms coverage without visible residue. On honed marble, deeper absorption produces strong stain resistance without altering texture.

For food-prep areas, apply Natural Stone Treatment WB; once cured, its non-film-forming chemistry leaves no transferable residue, aligning with food-contact safety expectations for residential kitchens.

Coverage: 100-200 square feet per gallon. Offers years of reliable protection between applications.

4. Siloxane PD (Pre-Diluted Water Repellent)

In moisture-rich environments, this ready-to-use blend shields marble shower tile and grout. Contractors rely on Siloxane PD as the best marble sealer for shower floors and bath enclosures because it limits darkening while staying vapor-permeable. The cured film withstands daily humidity and common cleaners.

Coverage: 125-175 square feet per gallon. Provides multi-year protection under typical exposure before re-treatment is needed.

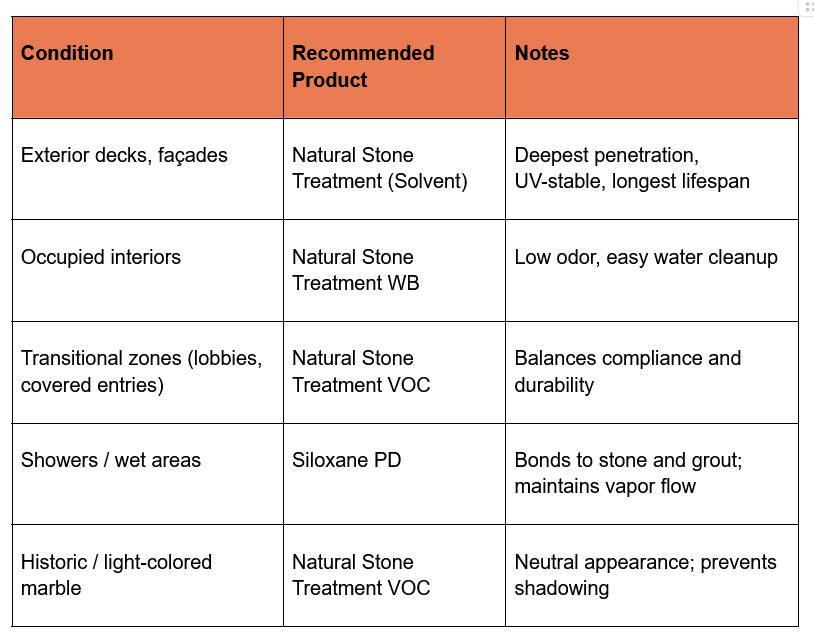

Matching the Right Sealer to Your Marble Surface

Application Guidelines for PROSOCO Marble Sealers

Proper surface preparation and controlled application determine performance. The steps below reflect standard field practice for penetrating sealers on marble and other calcareous stone.

- Prepare the Surface – Clean thoroughly and allow full drying. Any dust, residue, or previous coating will block penetration.

- Apply Evenly – Use low-pressure sprayers, brushes, or rollers to saturate the surface. On vertical stone, work from the bottom up and keep a continuous wet edge for uniform coverage.

- Allow Dwell Time – Let the product dwell 10–15 minutes so active molecules migrate into the pore structure.

- Manage Excess – Wipe or back-roll before drying. For solvent versions, provide cross-ventilation until the surface is fully dry to maintain indoor air quality.

- Environmental Conditions – Maintain ambient temperature between 40° F and 95° F. On large jobs, two light “wet-on-wet” passes yield better uniformity than one heavy coat.

When properly applied, these penetrating sealers leave no visible film, only breathable, water-repellent protection within the stone.

Maintenance and Re-Sealing Practices

To confirm protection remains effective, perform a quick water-drop test. Droplets should bead for several minutes without darkening the marble.

- Use pH-neutral cleaners—acids or strong alkalis strip the molecular bond.

- Prevent abrasion—dust-mop or use microfiber pads to keep grit from wearing the finish.

Inspection and Maintenance Frequency

High-traffic surfaces such as kitchen counters and entry floors should be checked every 12-18 months for water beading and gloss retention. Guest baths and other low-traffic interiors typically maintain protection for 3-5 years, while exterior decks sheltered by overhangs can perform for 8 years or more.

To confirm readiness for re-sealing, apply a few drops of water to a clean area, if darkening appears within ten seconds, reapplication is recommended. Regular inspection and pH-neutral cleaning maintain repellency, extend service life, and preserve the natural clarity of marble.

Understanding Sealer Performance on Marble

In everyday use, penetrating sealers guard against moisture and staining, not chemical etching. When acids such as citrus juice or vinegar contact marble, they react with calcium carbonate and leave a dull mark. Even high-performance sealers can’t stop that reaction, though regular pH-balanced cleaning and prompt spill removal remain essential.

Why Professionals Choose PROSOCO Marble Sealants

The company’s research in stone preservation spans decades of ASTM and field testing. Each formula undergoes ASTM testing for absorption reduction, vapor permeability, and color stability. Laboratory results on marble and limestone show more than 90% reduction in water absorption with no change in surface appearance. These formulations are commonly used on exterior stone restoration and preservation projects requiring durable, vapor-permeable protection.

With proper selection and maintenance, sealed marble retains its appearance for decades.

Protect Your Marble Surfaces with PROSOCO Sealants

Our sealants are formulated for professional results. Each formula provides long-term protection while maintaining the stone’s original finish. Contact us today for guidance on selecting and applying the correct sealer for your project’s conditions.