Brick walls face constant exposure to moisture, UV radiation, and freeze cycles. Without protection, these conditions break down the surface and weaken the structure over time. Choosing the best brick sealer depends on surface conditions, material behavior, and environmental exposure.

Why Brick Needs a Purpose-Built Sealer

Not all sealers behave the same way on clay-based masonry. Unlike concrete, brick often varies in porosity and surface composition, which makes product compatibility a critical concern. A film-forming coating may bond well to dense block but fail completely on dusty, open-faced brick. Many projects call for penetrating treatments that react below the surface rather than forming a layer on top.

Treatment That Works Below the Surface

These subsurface treatments reduce water absorption of the brick by filling micro-voids within the brick and mortar joints. When properly selected, these protective treatments allow the wall to remain breathable while resisting moisture intrusion. This is especially important in regions where freeze cycles can cause internal expansion and spalling if the best brick sealer isn’t selected for porous units.

Match the Sealer to the Environment and Substrate

Brick walls in interior spaces face different risks than those exposed to outdoor conditions. Occupied buildings often require low-VOC coatings that dry quickly without odor. For these spaces, water-based sealers are typically the safest and most practical option. They reduce airborne VOC exposure while minimizing disruption to daily operations.

Environmental Demands That Shape Sealer Selection

When selecting the best brick sealer for occupied interiors, vapor transmission and air quality must guide the chemistry choice. Exterior brick, especially in high-moisture or salt-prone zones, requires chemistry that can penetrate deeper and resist prolonged exposure. Siloxane blends or silane-based treatments are often used on these façades to form water-repellent channels inside the substrate. UV-stable formulas are preferred to prevent breakdown under sun exposure.

Application Conditions Directly Affect Sealer Performance

Even the most durable chemistry will fail if applied under the wrong site conditions.

- Jobsite moisture, residue from prep products, and ambient temperature all impact how the treatment behaves.

- Surface saturation is a common problem. Applying a sealer to damp brick can block penetration and create visible blotching or discoloration.

- Substrate cleanliness also matters. Any remaining acid, neutralizer, or dust left from grinding will interfere with bonding.

- Always test pH and moisture levels before applying a treatment.

A field mockup helps confirm how the brick will respond and whether visual changes—such as darkening or sheen—will occur. Mockups are an effective way to test how the brick sealer interacts with site-specific substrates, cleaners, and ambient moisture.

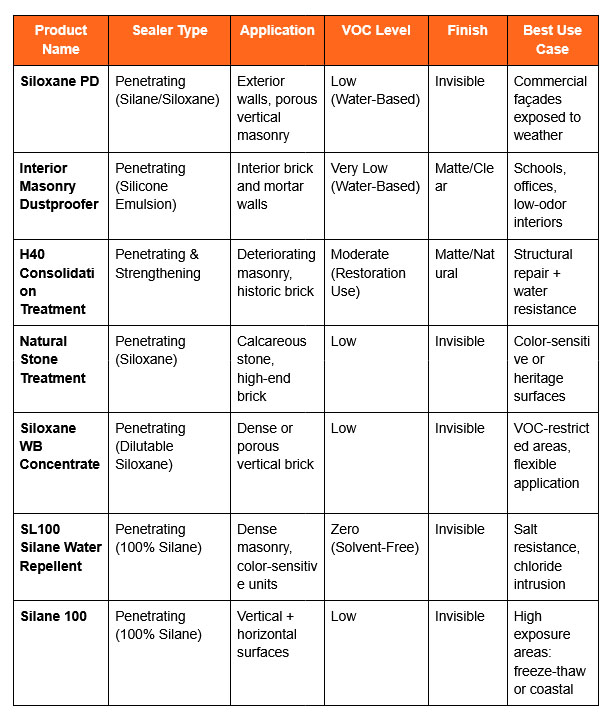

How Chemistry, VOC, and Finishes Influence Product Selection

Each sealer chemistry brings specific strengths and field limitations. This section outlines how performance factors relate to use case and jobsite needs.

Penetrating vs. Film-Forming Sealers

Penetrating sealers are designed to soak into the brick’s structure, where they react chemically to create hydrophobic barriers. They are ideal for vertical surfaces, porous brick, and freeze-thaw climates. Film-forming coatings sit on the surface, providing gloss or color enhancement, but may trap vapor and peel over time.

VOC Levels and Application Safety

Water-based products tend to emit fewer volatile organic compounds and are often required in occupied spaces. Solvent-based options can deliver deeper penetration but require additional safety precautions. Always review VOC content in relation to indoor air quality standards and fire safety restrictions.

Finishing Options and Aesthetic Changes

Some sealers leave no visible trace, while others create a wet-look or matte film. On heritage projects, clear and non-darkening treatments are often specified to preserve historical character. Always test a small area first to confirm color retention and gloss level.

Product Reviews – 7 Sealers That Meet Real Jobsite Demands

Each of the following treatments is designed to solve specific challenges in brick and masonry protection—from moisture intrusion to substrate degradation—based on how the surface performs in field conditions.

Siloxane PD

Siloxane PD penetrates deep into masonry surfaces and chemically bonds within the pore structure. It reduces water absorption without forming a surface film, allowing vapor to escape while resisting stains, efflorescence, and freeze-related damage. It performs under high-exposure conditions on brick, block, and other porous vertical substrates.

Interior Masonry Dustproofer

Formulated for interior walls in schools, offices, and public buildings, Interior Masonry Dustproofer controls dusting without altering surface appearance. It binds loose particles and dries to a clear matte finish. Because it’s water-based and low in VOCs, it meets indoor air quality requirements and cures quickly in occupied spaces.

H40 Consolidation Treatment

Designed for historic or deteriorating masonry, H40 Consolidation Treatment penetrates and strengthens weakened brick and mortar by chemically bonding within the substrate. It increases compressive strength and provides water resistance while maintaining breathability. It’s commonly used in preservation and restoration projects where structural reinforcement is needed without visible change.

Natural Stone Treatment

Though originally developed for calcareous materials like limestone and marble, Natural Stone Treatment performs well on high-value brick masonry where surface alteration is unacceptable. It penetrates to repel water without forming film, helping prevent biological staining and weather-driven deterioration while preserving surface texture and color.

Siloxane WB Concentrate

Siloxane WB Concentrate adapts to both porous and dense masonry types. It forms a durable, breathable barrier that resists waterborne contaminants and staining. On brick, it achieves deep penetration with minimal darkening and is often used where solvent-based products are restricted.

SL100 “Neat” Silane Water Repellent

A solvent-free silane designed for dense and color-sensitive masonry. SL100 penetrates thoroughly without changing appearance, offering invisible protection against water and chloride ingress. Because it contains no carrier solvent, it delivers low volatility, high coverage, and reduced jobsite odor.

Silane 100

Silane 100 is used on vertical and horizontal applications where deep penetration and chloride resistance are required. It’s especially effective in coastal or freeze-prone environments. It leaves no surface film, supports high coverage rates, and complies with VOC regulations for breathable exterior protection.

Sealer Lifespan, Reapplication, and Maintenance

No coating is permanent. The durability of any brick sealer depends on traffic, UV load, and environmental wear. Reapplication cycles vary by chemistry, but most treatments last 3–7 years under typical conditions.

The best brick sealer won’t prevent wear indefinitely, but it will extend service life and slow absorption under real exposure conditions.

- Inspection and spot testing should be scheduled annually.

- Walls exposed to sprinklers, landscaping runoff, or deicing salts may require more frequent retreatment.

- Use gentle cleaners to avoid stripping the treatment prematurely, and never apply new sealer over failing film unless fully removed.

Brick sealing success depends on surface preparation, chemistry compatibility, and actual field performance.

Choose Based on Field Behavior, Not Label Claims

Always select a product that matches the substrate type, expected exposure, and application window. A product that performs well in one condition may fail entirely in another.

Field performance—not product marketing—should guide selection of the best brick sealer for long-term protection. When in doubt, test a small section under real jobsite conditions. Confirm visual results, water repellency, and drying behavior before proceeding with full application.

Protect Brick Without Trapping Moisture – Contact PROSOCO for Proven Masonry Sealers

Sealing doesn’t have to mean trapping moisture or altering a wall’s appearance. We offer penetrating water repellents and interior dustproofers that perform under real jobsite conditions. Contact us today for more information.